INNOVATION LABS

Smart Factory

The Smart Factory Center at TANSAM (Tamil Nadu Smart and Advanced Manufacturing Centre), located at TIDEL Park, Chennai, is a state‑of‑the‑art facility that enables industries, MSMEs, startups, and students to adopt Industry 4.0 technologies. Powered by Siemens Xcelerator solutions, the centre provides access to automation, IoT, robotics, and digital twin platforms that modernize operations and build future‑ready factories across Tamil Nadu.

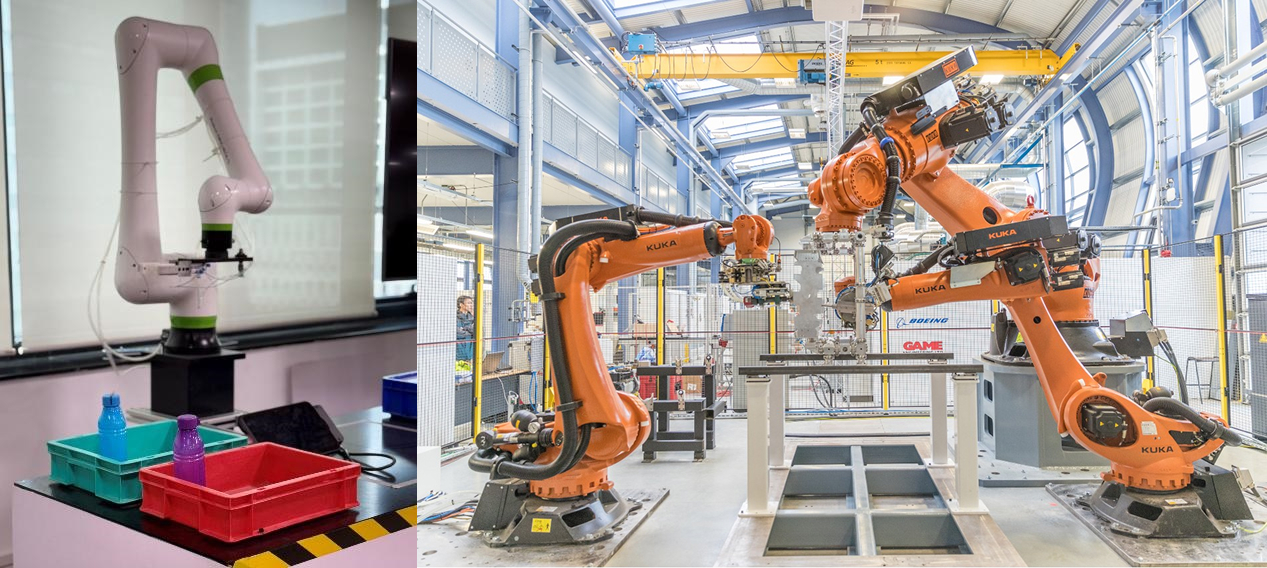

We're committed to a future where manufacturing is more efficient, ethical, and environmentally conscious. Our robotic solutions are a testament to that commitment, working tirelessly to build a better tomorrow, one product at a time.

- Increased Productivity: 40% improvement in production throughput.

- Reduced Waste: 70% decrease in material scrap.

- Higher Precision: Unmatched accuracy for complex component assembly.

How It Helps Companies

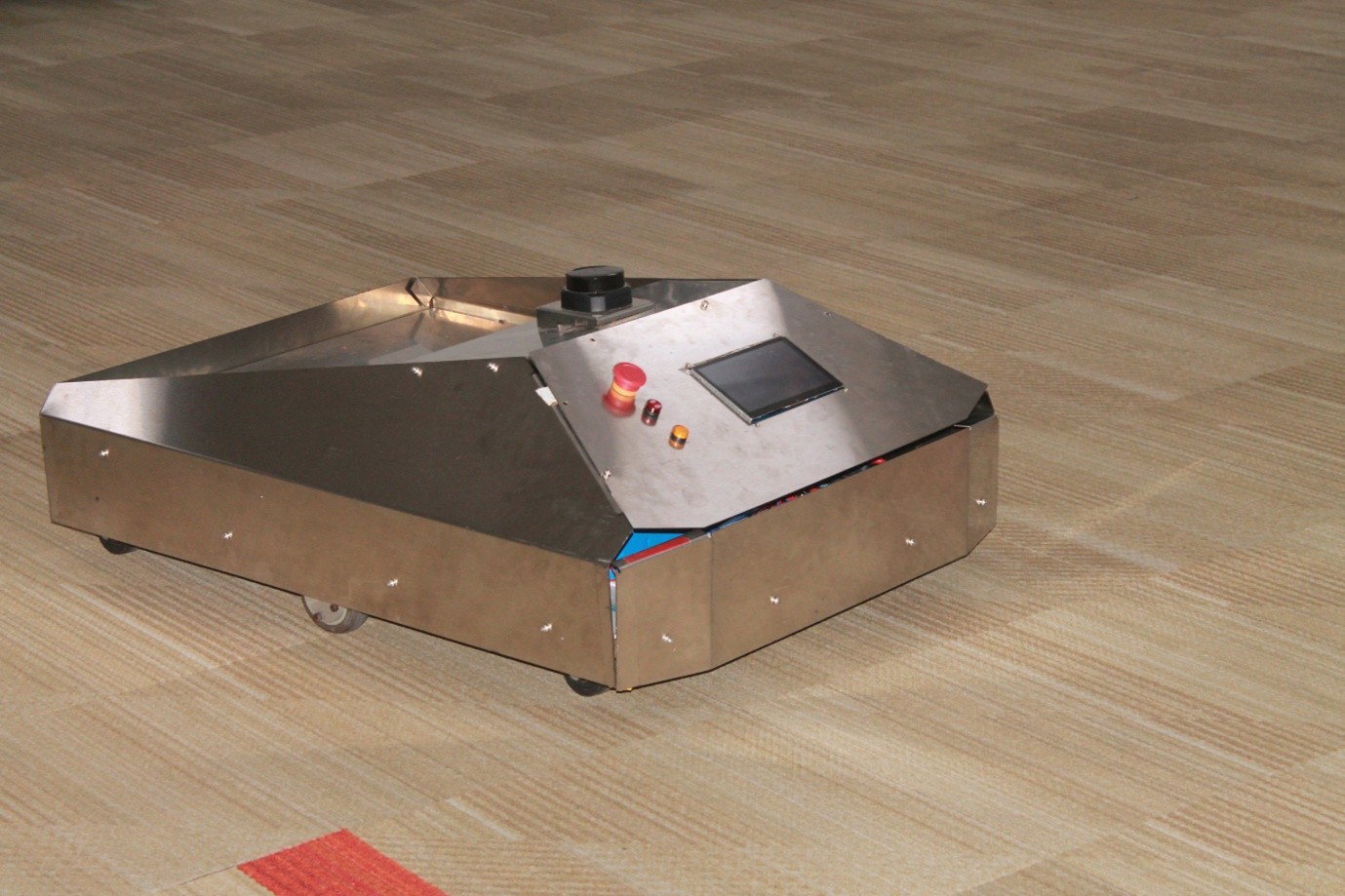

- Automation & robotics streamline production and reduce downtime

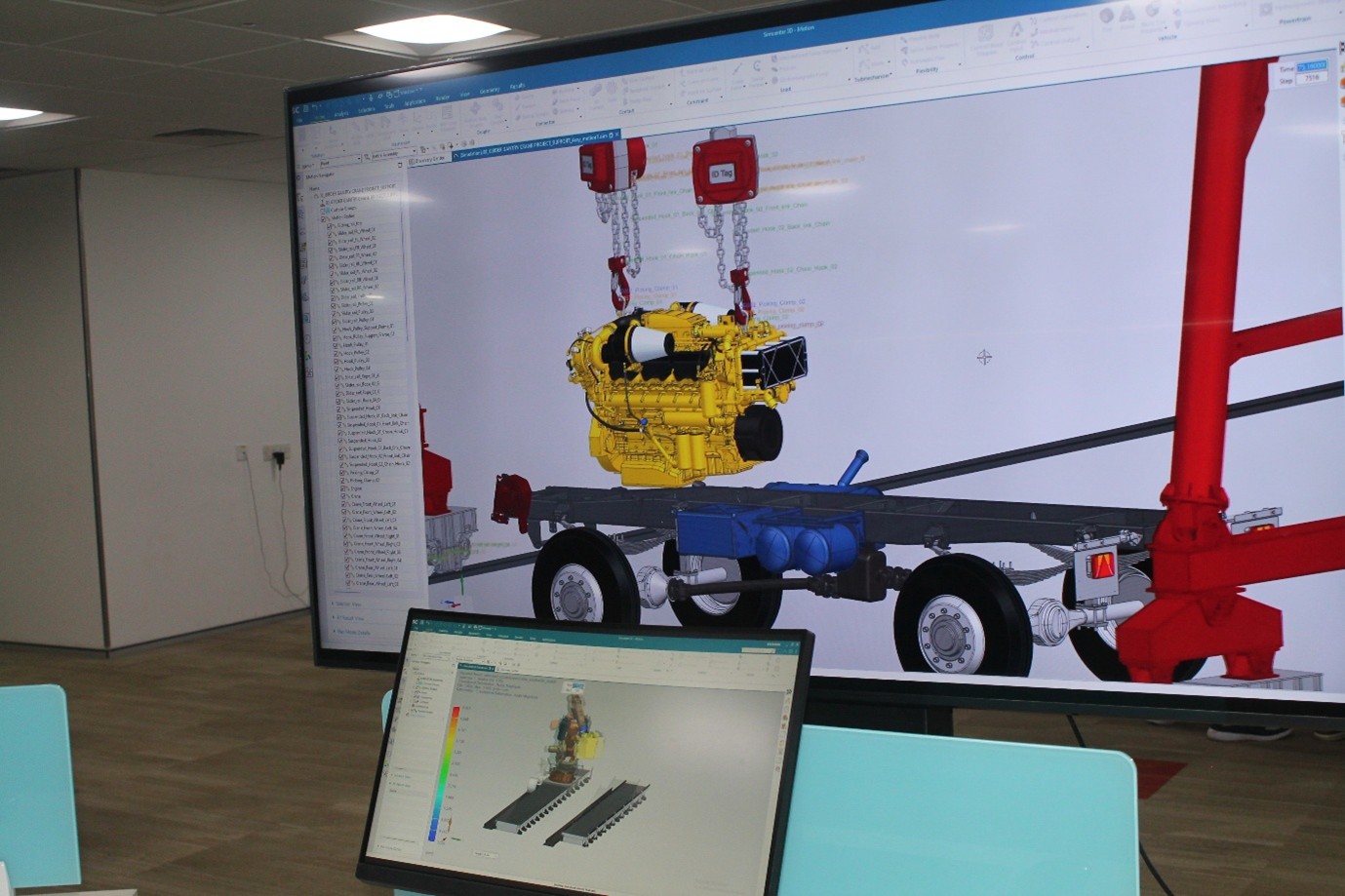

- Digital twin technology allows virtual testing and optimisation of factory workflows

- Data analytics & AI improve decision‑making and efficiency.

- Cybersecurity solutions protect connected manufacturing systems.

Core Solutions

- Automation & Robotics – PLCs, robotics integration, smart production lines.

- Digital Twin Technology – Virtual factory simulations for design and optimisation.

- Data Analytics & AI – Industrial insights for smarter decisions.

Services Offered

- Smart factory design and implementation.

- Industrial training programs.

- Collaborative projects with MSMEs and corporates.

Testimonials

“TANSAM’s Smart Factory Center helped us modernize our operations. We reduced downtime and improved efficiency significantly.” – MSME Partner, located at Tamilnadu.

“Our students gained hands‑on Industry 4.0 experience that directly improved their employability.” – Professor, Engineering College, located at Tamilnadu.

Case Study

- A Coimbatore‑based textile MSME partnered with the Smart Factory Center to digitize its production line.

- A digital twin was created to simulate workflows and identify bottlenecks.

- Predictive analytics reduced downtime by 25% and improved energy efficiency.

- Outcome: Faster turnaround times, reduced operational costs, and improved competitiveness in Tamil Nadu’s textile industry.

Frequently Asked Questions (FAQ)

- Q1: Who can access the Smart Factory Center? MSMEs, startups, enterprises, and academic institutions across Tamil Nadu.

- Q2: What technologies are used? The centre uses Siemens Xcelerator portfolio, PLCs, robotics platforms, and AI‑driven analytics.

- Q3: How does it benefit MSMEs? It reduces costs, improves efficiency, and accelerates innovation.