INNOVATION LABS

Extended Reality (XR) – Virtual & Augmented Reality Solutions

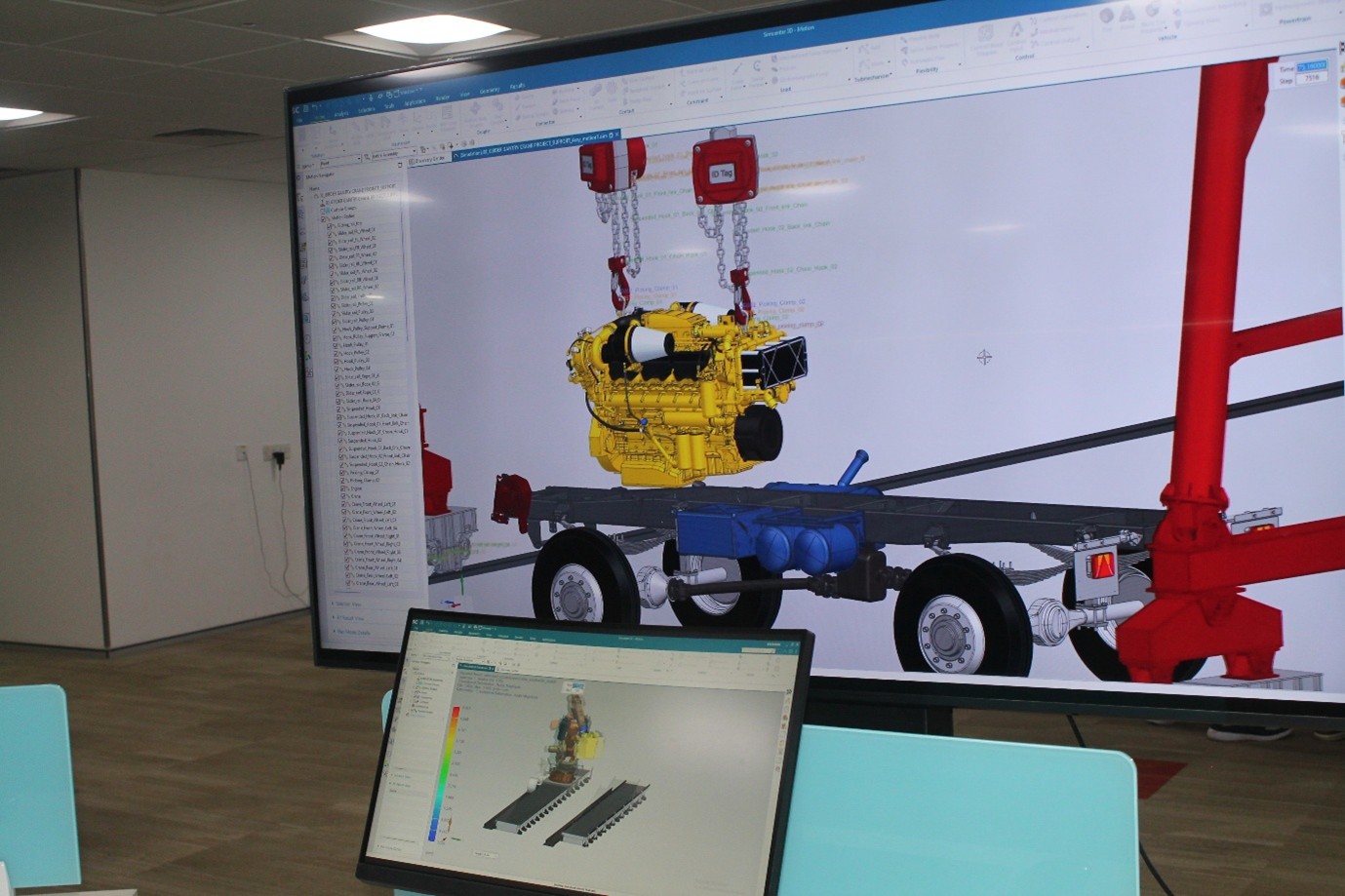

The AR/VR Lab at TANSAM (Tamil Nadu Smart and Advanced Manufacturing Centre), located at TIDEL Park, Chennai, is a dedicated facility for immersive technologies in manufacturing and training. Powered by Siemens Xcelerator solutions, the lab integrates Augmented Reality (AR) and Virtual Reality (VR) to create digital twins, immersive simulations, and interactive learning environments for MSMEs, startups, and academic institutions across Tamil Nadu.

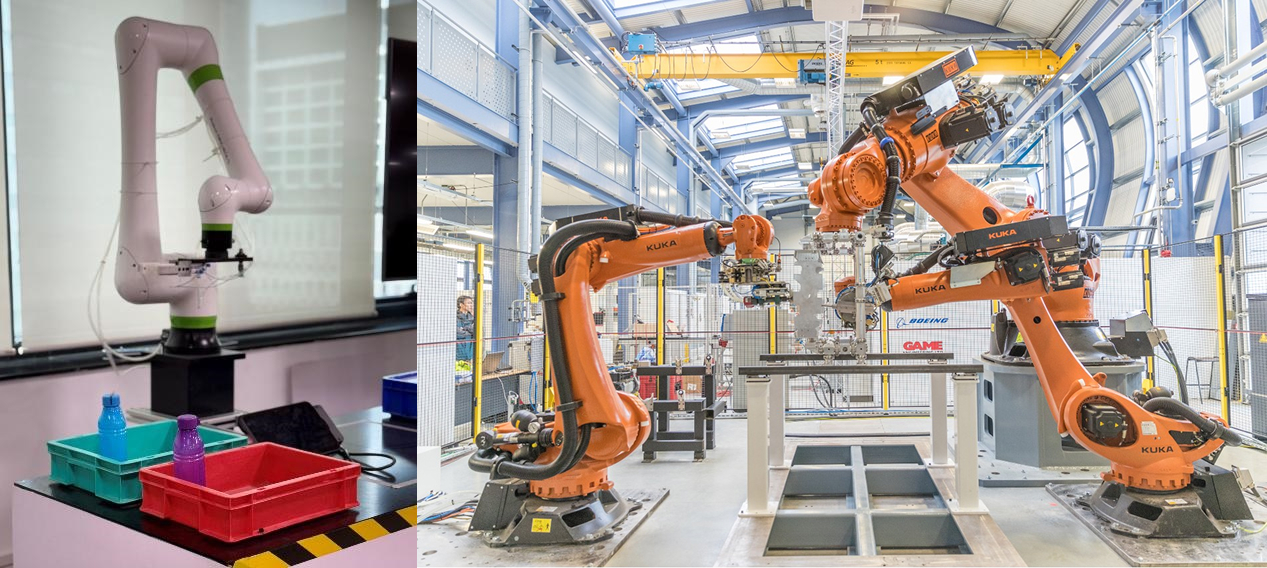

These technologies are widely used in industries such as entertainment, education, healthcare, and engineering. VR is commonly used to create immersive gaming experiences and training simulations, while AR enhances real-world tasks by providing digital guidance and interactive learning opportunities.

How It Helps Companies

- Enhanced training – AR/VR reduces training time and improves knowledge retention.

- Cost savings – Virtual prototyping eliminates the need for physical models.

- Improved safety – Simulations allow risk‑free testing of industrial processes.

- Faster innovation – Digital twins accelerate product design and validation.

- Regional impact – Affordable access for MSMEs in across Tamilnadu.

Core Solutions

- Augmented Reality (AR) – Digital overlays for real‑time guidance on equipment.

- Virtual Reality (VR) – Immersive factory simulations for design validation and workforce training.

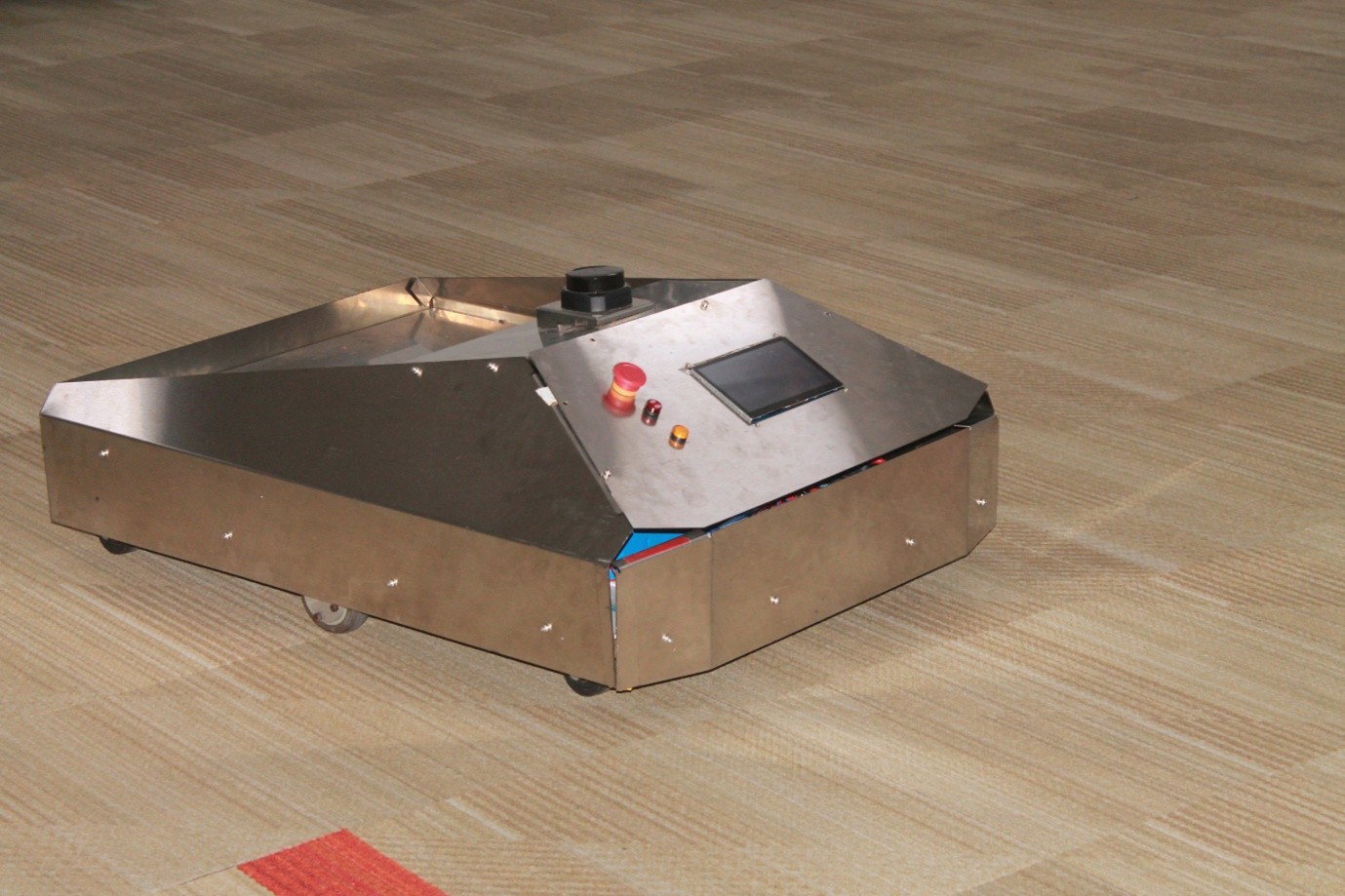

- Digital Twin Integration – AR/VR combined with IoT and analytics for predictive maintenance.

- Immersive Training Programs – Hands‑on Industry 4.0 learning for students, startups, and MSMEs.

Services Offered

- AR/VR application development

- Digital twin simulations

- Industrial training programs

- Collaborative projects with universities and corporates

Testimonials

“The AR/VR Lab gave our MSME team the ability to test processes virtually before implementation. It saved us both time and money.” – MSME Partner, located at Tamilnadu.

“Our students gained hands‑on AR/VR experience that directly improved their employability in Tamil Nadu’s manufacturing sector.” – Professor, Engineering College, located at Tamilnadu.

Case Study

- A Madurai‑based engineering college partnered with the AR/VR Lab to modernize student training.

- Students explored virtual factory environments through VR simulations.

- AR overlays provided step‑by‑step instructions on lab equipment.

- Digital twin integration enabled real‑time monitoring of machine performance.

- Outcome: Training time reduced by 40%, student engagement increased, and graduates gained practical Industry 4.0 skills.

Frequently Asked Questions (FAQ)

- Q1: Who can access the AR/VR Lab? MSMEs, startups, enterprises, and academic institutions across Tamil Nadu.

- Q2: What technologies are used? The lab uses Siemens NX, Solid Edge, Unity, and Siemens Xcelerator portfolio.

- Q3: How does AR/VR benefit MSMEs? It reduces costs, improves safety, and accelerates product innovation.