INNOVATION LABS

Materials & Specifications for 3D Printing

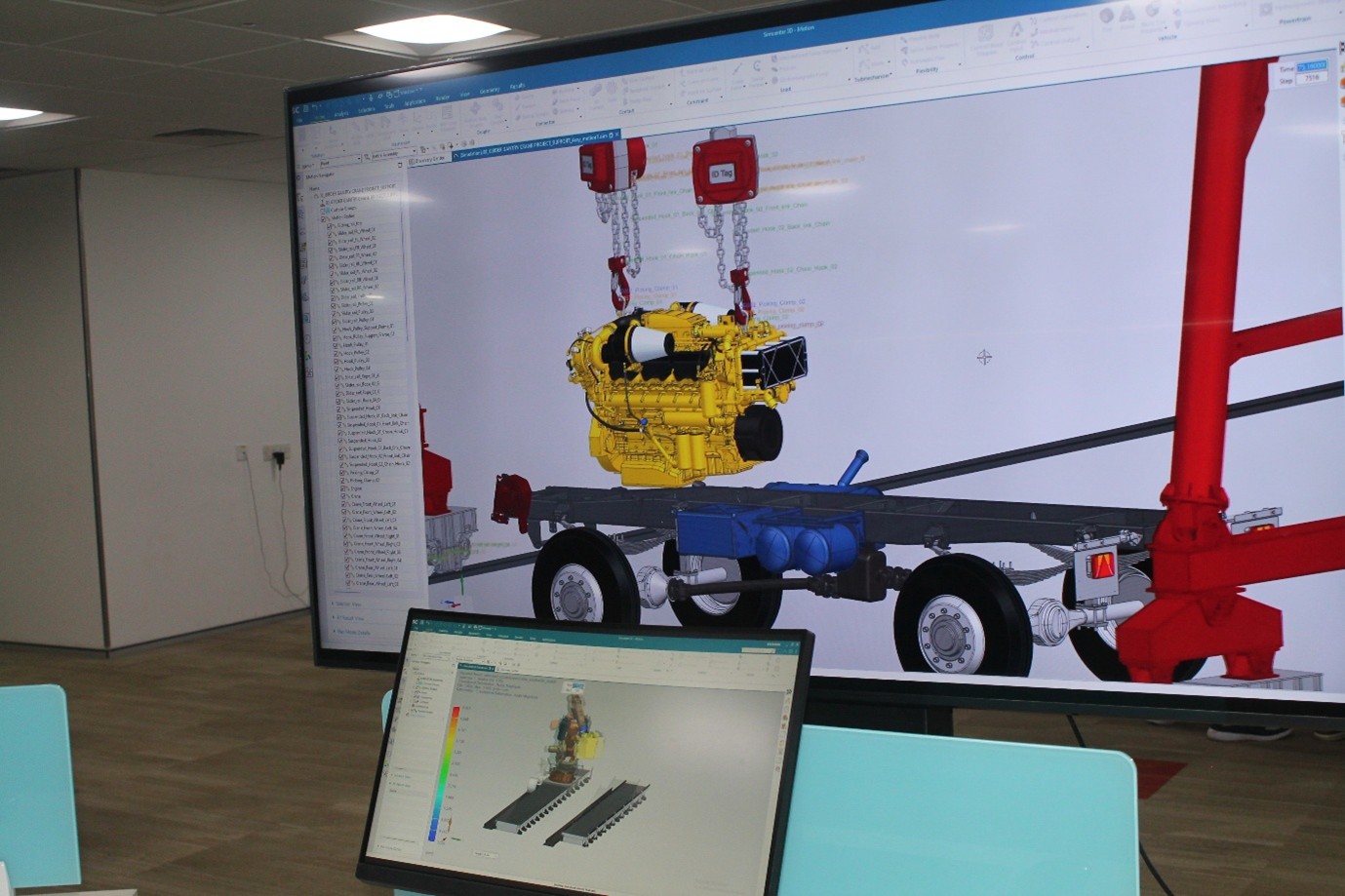

The Innovative Manufacturing Lab at TANSAM (Tamil Nadu Smart and Advanced Manufacturing Centre), located at TIDEL Park, Chennai, is a dedicated hub for reverse engineering, additive manufacturing, and 3D printing technologies. Powered by Siemens Xcelerator solutions, the lab provides MSMEs, startups, and students across Tamil Nadu with access to advanced tools that accelerate product innovation, reduce costs, and improve competitiveness.

Our approach promotes flexibility and scalability, empowering industries to meet evolving demands efficiently. At TANSAM, innovation drives sustainable and future-ready manufacturing solutions.

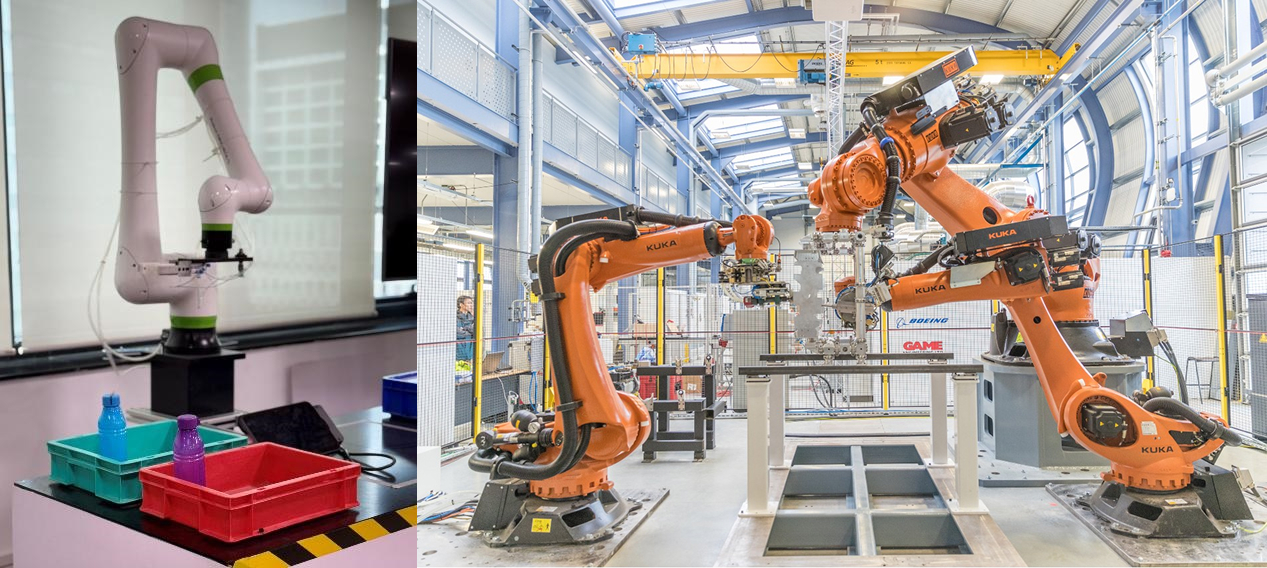

Innovative Manufacturing Centre hosts two critical functions: Reverse Engineering and Rapid Prototyping.

- Reverse Engineering digitizes and creates digital twins of legacy products, using 3D scanning and parametric data to recreate and improve 3D models.

- Rapid prototyping accelerates product development, enabling design iteration and validation — leading to shorter time-to-market.

How It Helps Companies

- Rapid prototyping: 3D printing enables faster product development cycles.

- Cost efficiency: Reverse engineering reduces tooling and manufacturing expenses.

- Innovation: Additive manufacturing allows complex geometries not possible with traditional methods.

- Local support: Across Tamilnadu MSMEs gain affordable access to cutting-edge technology.

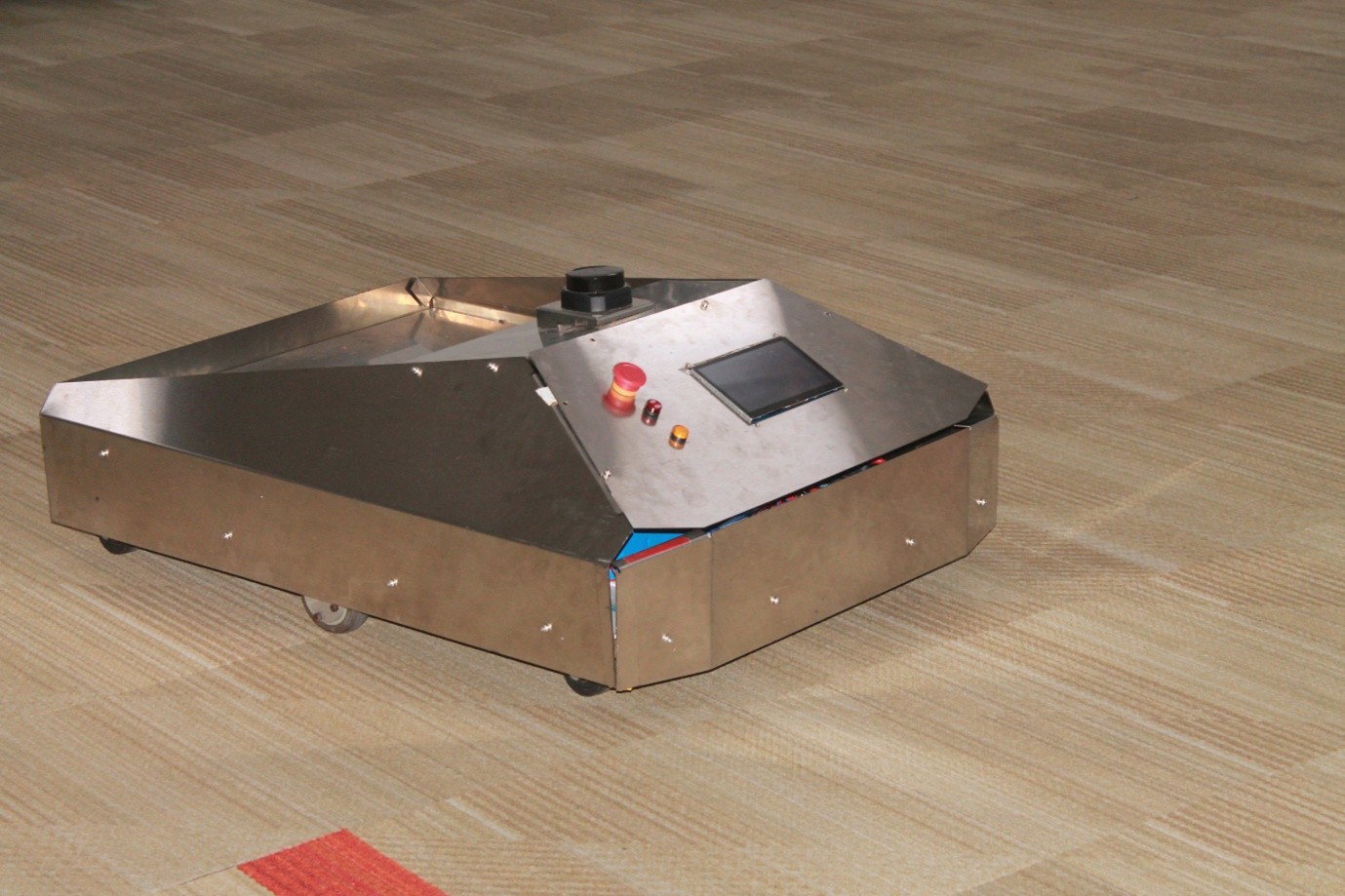

- Digital transformation: Integrates with PLM and digital twin workflows for Industry 4.0 readiness.

Core Solutions

- Reverse Engineering: Handheld 3D scanning (Calibry Mini) and reconstruction using Siemens NX and Solid Edge.

- 3D Metal Printing: Markforged printers for lightweight, high-strength prototypes.

- Additive Manufacturing: Layer-by-layer printing with seamless CAD-to-print workflows.

Services Offered

- 3D scanning and modeling

- Reverse engineering of legacy components

- Additive manufacturing and prototyping

- Training programs for students and MSMEs

Testimonals

“TANSAM’s Innovative Manufacturing Lab helped us prototype parts quickly and cost-effectively. It transformed our production process.” — MSME Partner, located at Tamilnadu.

“Our students gained hands-on experience with 3D printing and reverse engineering, making them job-ready for Industry 4.0.” — Professor, Engineering College, located at Tamilnadu.

Case Study

- The worn-out part was scanned using the alibry Mini 3D scanner.

- A Chennai-based automotive MSME needed a discontinued engine component.

- Engineers reverse-engineered the part in Siemens NX and optimized the design.

- A high-strength prototype was produced in 72 hours using Markforged’s metal printer.

- Reduced downtime, avoided costly tooling, and demonstrated the lab’s ability to deliver end-to-end smart manufacturing solutions.

Materials 3D Printed

- Stainless Steel (17-4 PH)

- Copper

- Inconel 625

- Tool Steel H13, A2 & D2

Build Volume

- Length: 300 mm

- Width: 220 mm

- Height: 180 mm

Key Features

- Print Bed Heated: Vacuum-sealed print sheet, auto bed leveling

- Print System: Two nozzles – metal material and release material

- Release Material: Ceramic (consumed at 1:10 ratio to metal spools)

- Supports: Metal material with ceramic release layer

- Supplied Software: Eiger Cloud (other options available at cost)