INNOVATION LABS

Research Centre For Asset Performance

The Research Centre for Asset Performance at TANSAM (Tamil Nadu Smart and Advanced Manufacturing Centre), located in TIDEL Park, Chennai, is a dedicated hub for predictive maintenance, reliability engineering, and performance optimisation of industrial assets. Powered by Siemens Xcelerator solutions, the centre supports MSMEs, startups, and enterprises across Tamil Nadu in improving equipment uptime, reducing operational costs, and achieving sustainable manufacturing excellence.

To monitor real-time, we strategize and overcome challenges that include data collection, local processing, edge / hybrid computing to offer several benefits such as reduced latency, improved scalability, enhanced privacy, and cost-efficiency.

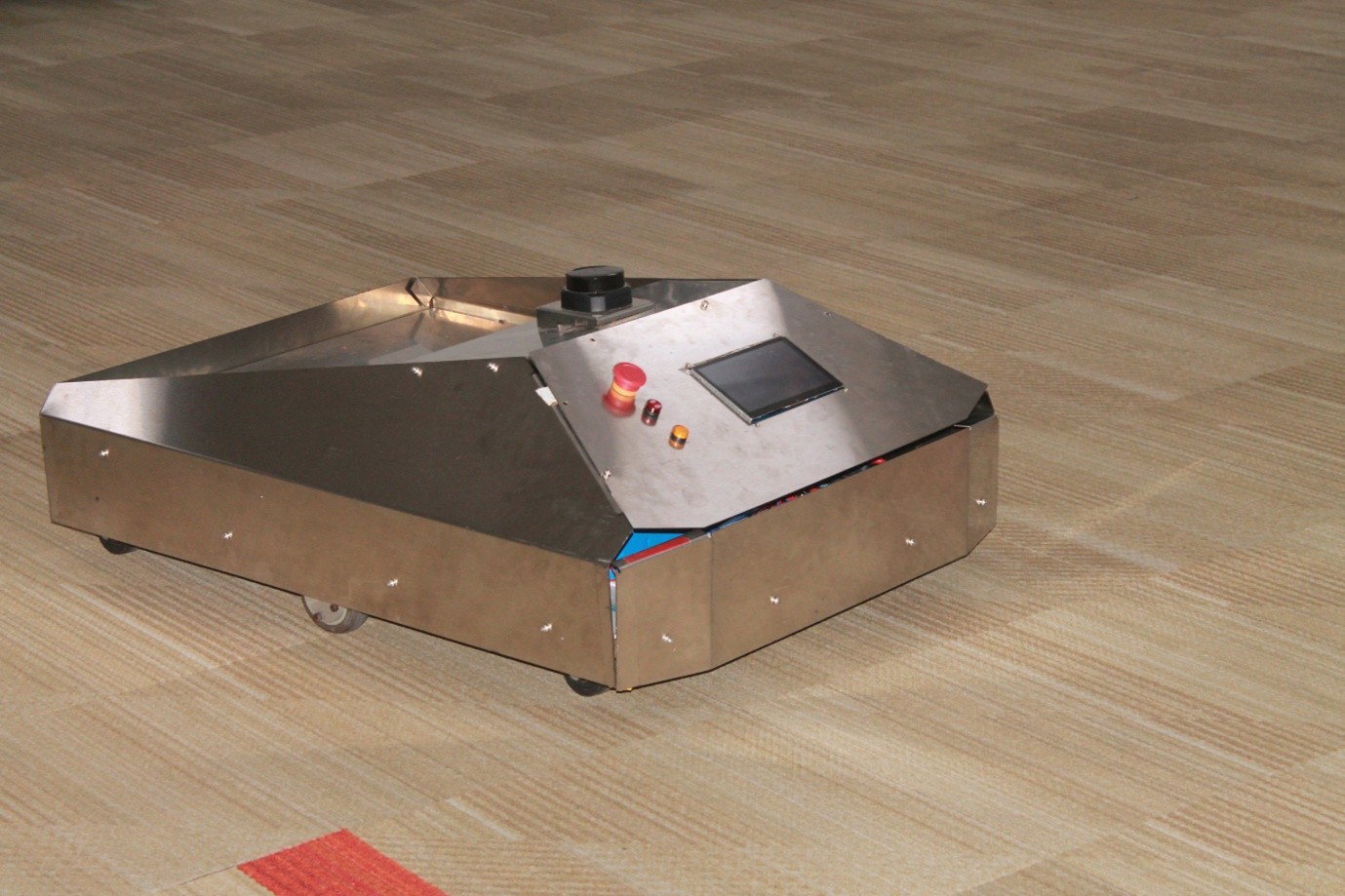

- IoT

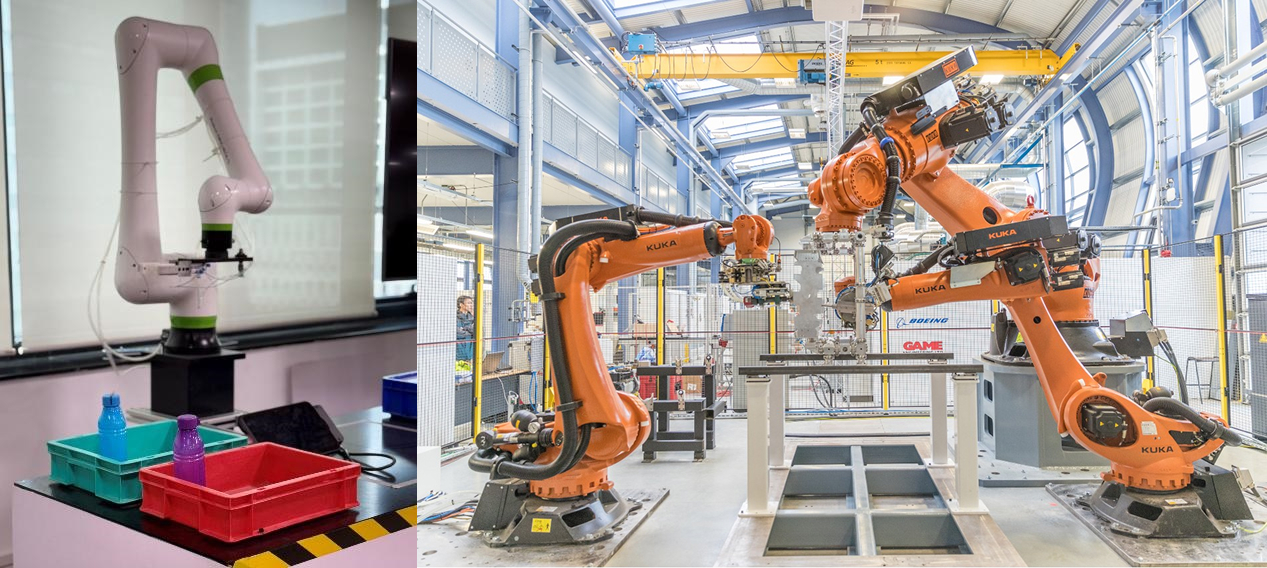

- Automation

- Robotics

- Big Data Analysis

- Communication Protocol

Internet of Things (IoT) Includes

Sensors, microcontrollers, radio frequency, MQTT, user interface, and applications.

Big Data Includes

The process of uncovering trends, patterns, and correlations from large amounts of raw data to help make informed decisions.

How It Helps Companies

- Predictive maintenance – IoT sensors and analytics detect issues before breakdowns occur.

- Reduced downtime – Real‑time monitoring improves asset reliability and availability.

- Cost savings – Optimised maintenance schedules lower repair and replacement costs.

- Sustainability – Efficient asset utilisation reduces energy consumption and waste.

- Local impact – Affordable access for MSMEs in across Tamilnadu.

Core Solutions

- Asset Health Monitoring – Real‑time IoT‑driven insights into equipment performance.

- Predictive Analytics – AI models forecast failures and optimise maintenance strategies.

- Reliability Engineering – Systematic methods to improve asset lifecycle and performance.

Services Offered

- Asset performance audits

- Predictive maintenance implementation

- Reliability engineering consulting

- Training programs for MSMEs and students

Testimonials

“The Asset Performance Centre helped us cut downtime and improve machine reliability. It saved us lakhs in maintenance costs.” — MSME Partner, located at Tamilnadu.

“Students gained practical knowledge in predictive maintenance and digital twin technology, making them industry‑ready.” — Professor, Engineering College, located at Tamilnadu.

Case Study

- A Salem-based cement MSME faced frequent machine breakdowns that disrupted production.

- IoT sensors were deployed to monitor asset health in real time.

- Predictive analytics identified failure patterns in advance.

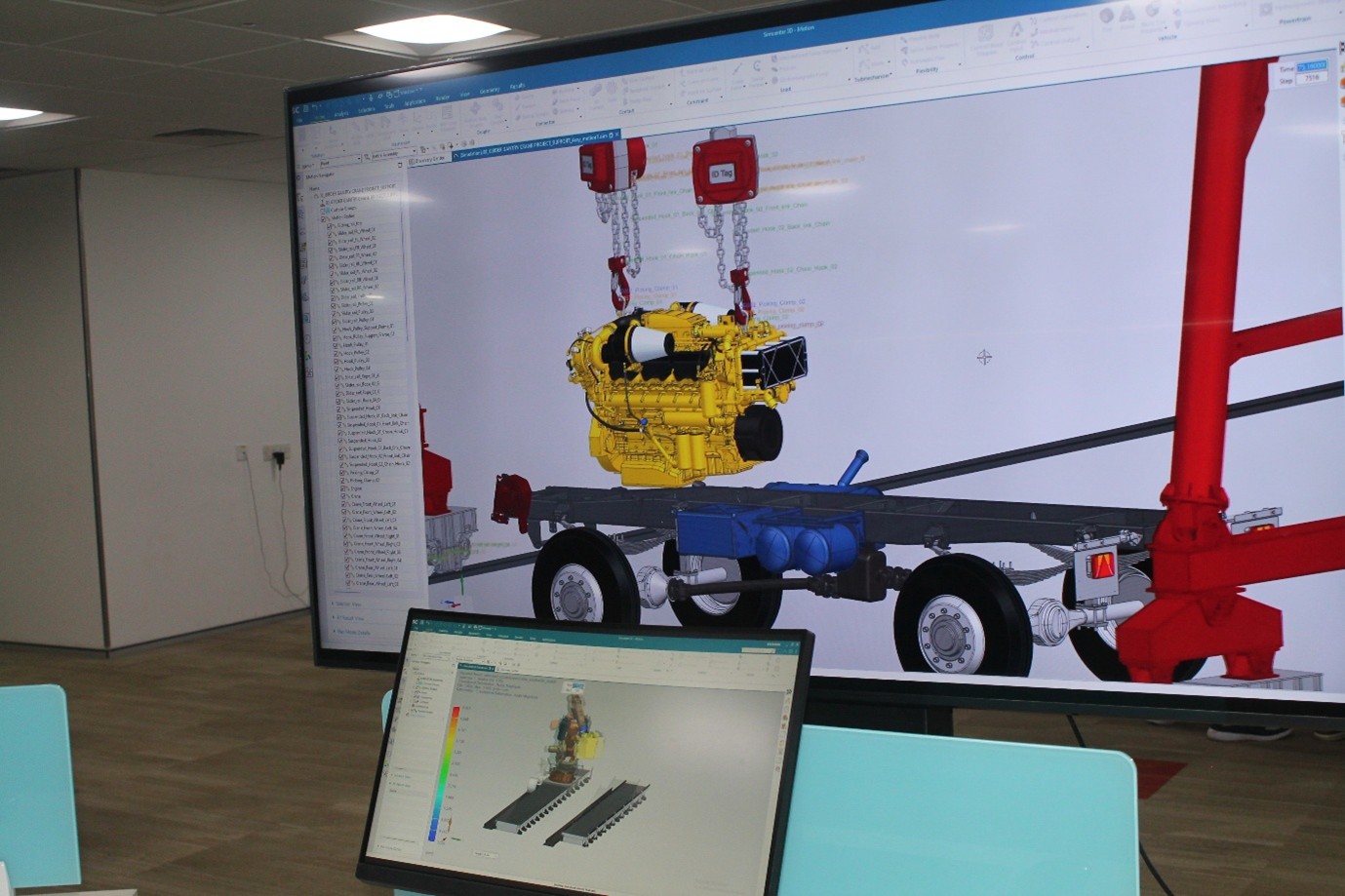

- Maintenance schedules were optimised using digital twin simulations.

- Outcome: Downtime reduced by 35%, maintenance costs lowered, and production efficiency improved significantly.

Frequently Asked Questions (FAQ)

- Q1: Who can access the Research Centre for Asset Performance? MSMEs, startups, enterprises, and academic institutions across Tamil Nadu.

- Q2: What technologies are used? The centre uses IoT sensors, Siemens Xcelerator, predictive analytics, and digital twin platforms.

- Q3: How does it benefit MSMEs? It reduces downtime, lowers costs, and improves asset reliability.