INNOVATION LABS

Product Innovation Center

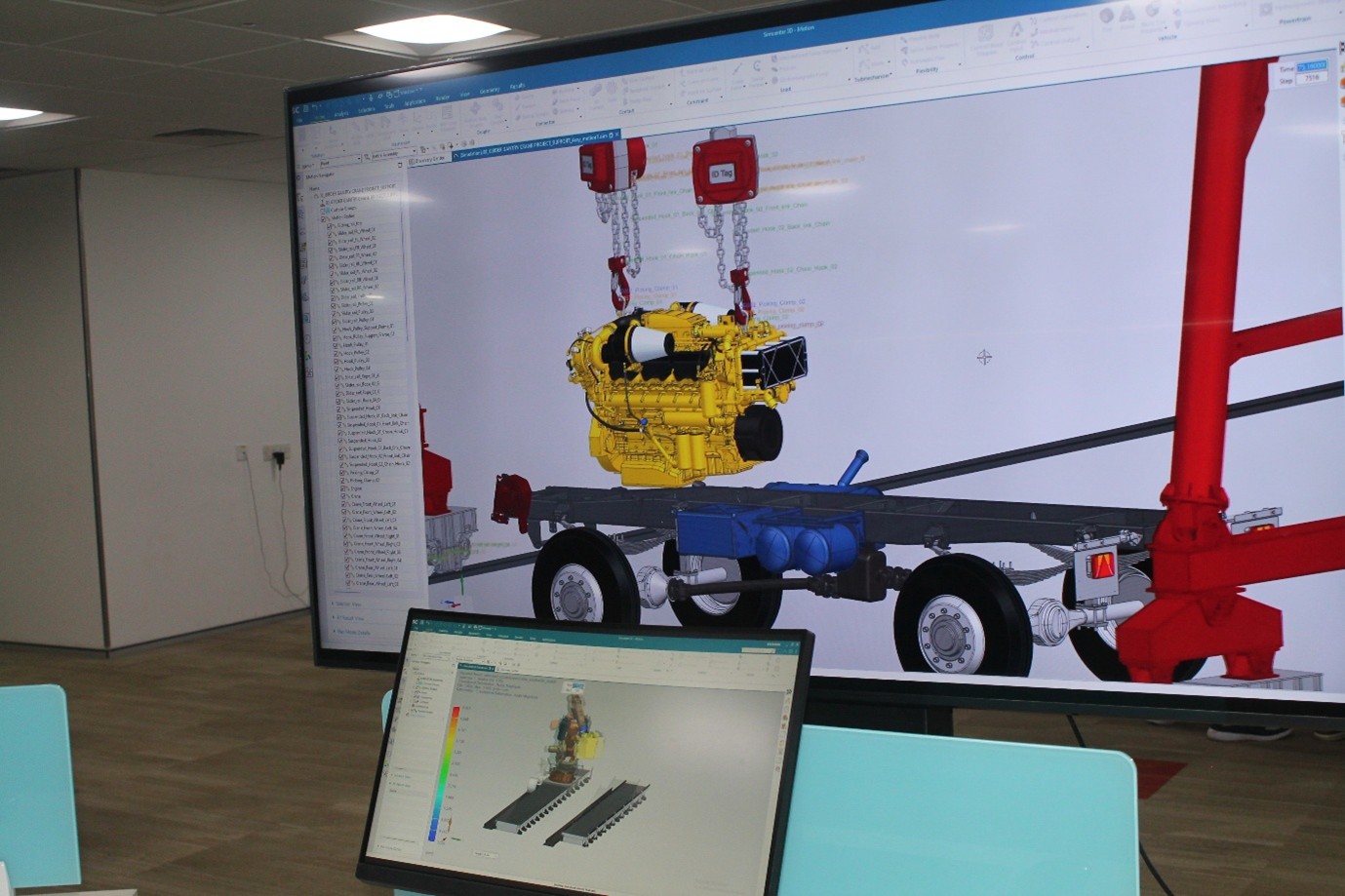

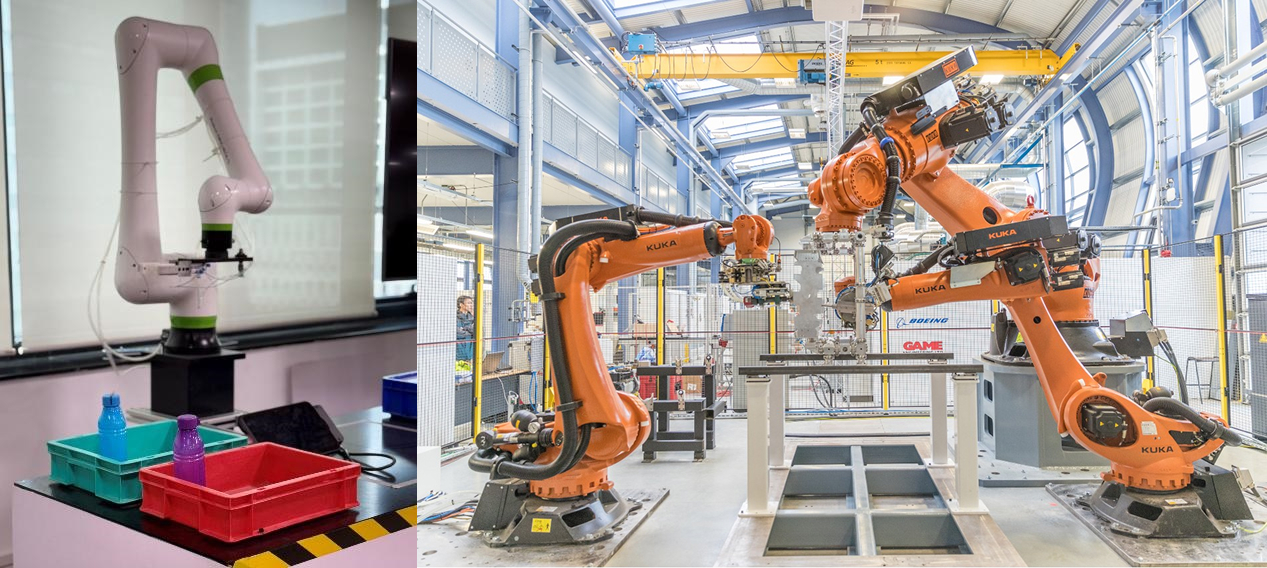

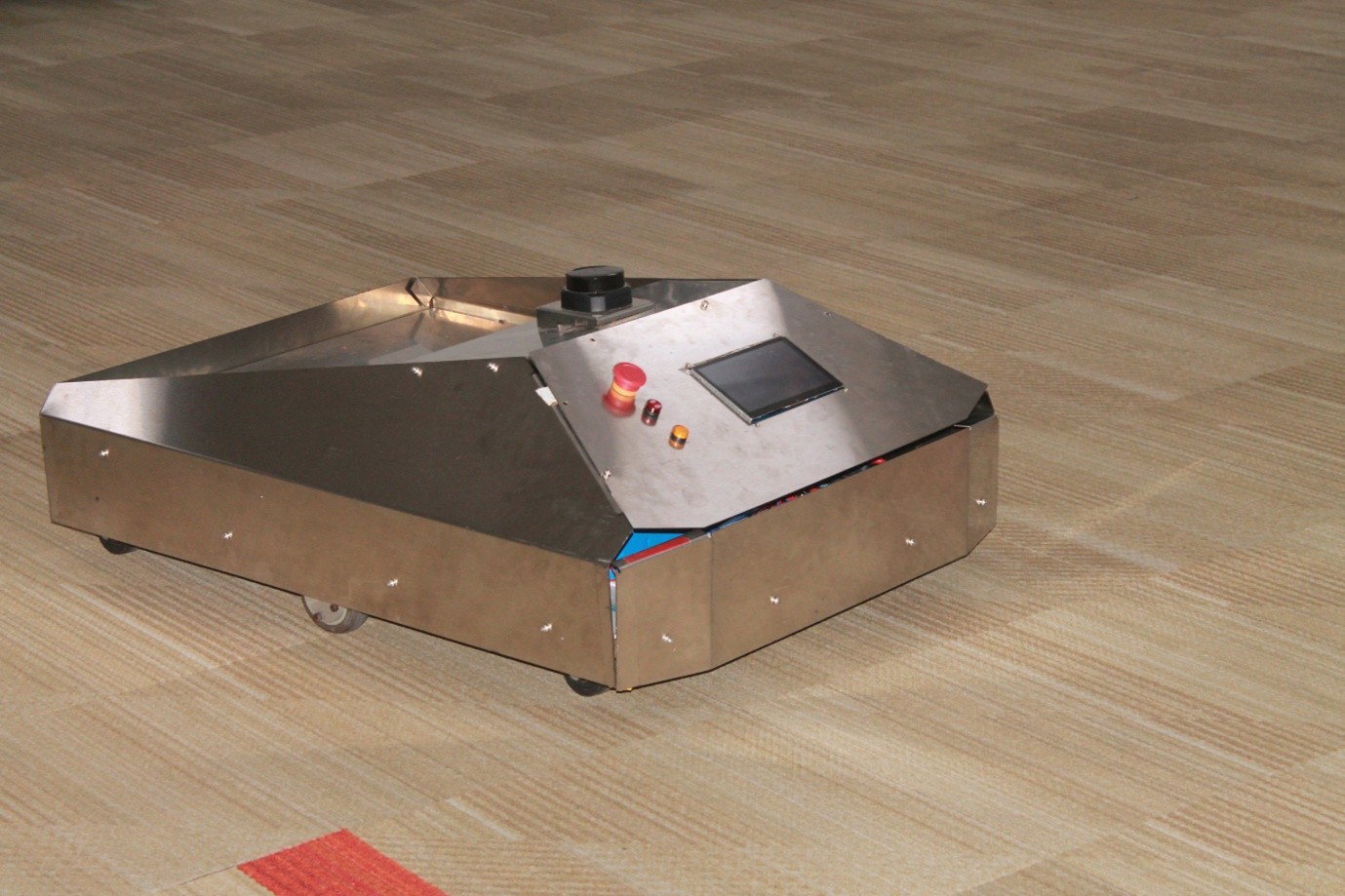

The Product Innovation Center at TANSAM (Tamil Nadu Smart and Advanced Manufacturing Centre), located at TIDEL Park, Chennai, is a hub for design thinking, prototyping, and product development. It empowers MSMEs, startups, and students across Tamil Nadu to transform ideas into market‑ready solutions using Siemens Xcelerator portfolio, CAD/CAE tools, and rapid prototyping technologies.

Core Capabilities

- Data Capture

- Pre-processing

- Segmentation and Surface Fitting

- CAD Model Creation

Additional Inclusions

- Data from existing designs

- Competitor comparison

- Duplication & repairs

- Old designs, before CAD

- Finite Element Data

Process Includes

- Facet Body Modification

- Decimate Facet Body

- Subdivide Facet Body

- Snipping

- Fill Holes

- Geometry Creation/Modification

- Freeform Modeling

- Synchronous Modeling

How It Helps Companies

- Accelerates product development: From concept to prototype in record time.

- Reduces costs: Virtual design and simulation lower expenses on physical models.

- Boosts innovation: Access to advanced CAD/CAE tools and additive manufacturing.

- Supports MSMEs: Affordable access for industries in across Tamilnadu and India.

- Academic collaboration: Students gain hands‑on experience with product innovation workflows.

Core Solutions

- Design Thinking Workshops – Structured ideation and problem-solving sessions.

- CAD/CAE Integration – Siemens NX, Solid Edge, and simulation tools.

- Rapid Prototyping – 3D printing and additive manufacturing for quick iterations.

Services Offered

- Product design and development consulting

- Prototyping and testing services

- Innovation training programs

- Collaborative projects with MSMEs and universities

Testimonials

“The Product Innovation Center helped us turn our idea into a prototype quickly. It saved us months of effort.” – Startup Founder, located at Tamilnadu.

“Our students gained practical knowledge in design thinking and CAD tools, making them industry‑ready.” – Professor, Engineering College, located at Tamilnadu.

Case Study

- A Coimbatore-based startup approached the Product Innovation Center to develop a new medical device prototype.

- Used design thinking workshops to refine the concept.

- Designed the product in Siemens NX with simulation for performance validation.

- Produced a working prototype using 3D printing within two weeks.

- Outcome: Reduced development cycle by 40%, secured investor interest, and accelerated market entry.

Frequently Asked Questions (FAQ)

- Q1: Who can access the Product Innovation Center? MSMEs, startups, enterprises, and academic institutions across Tamil Nadu.

- Q2: What technologies are used? The centre uses Siemens NX, Solid Edge, CAD/CAE simulation tools, and 3D printing technologies.

- Q3: How does it benefit MSMEs? It reduces costs, accelerates product development, and improves innovation capacity.