INNOVATION LABS

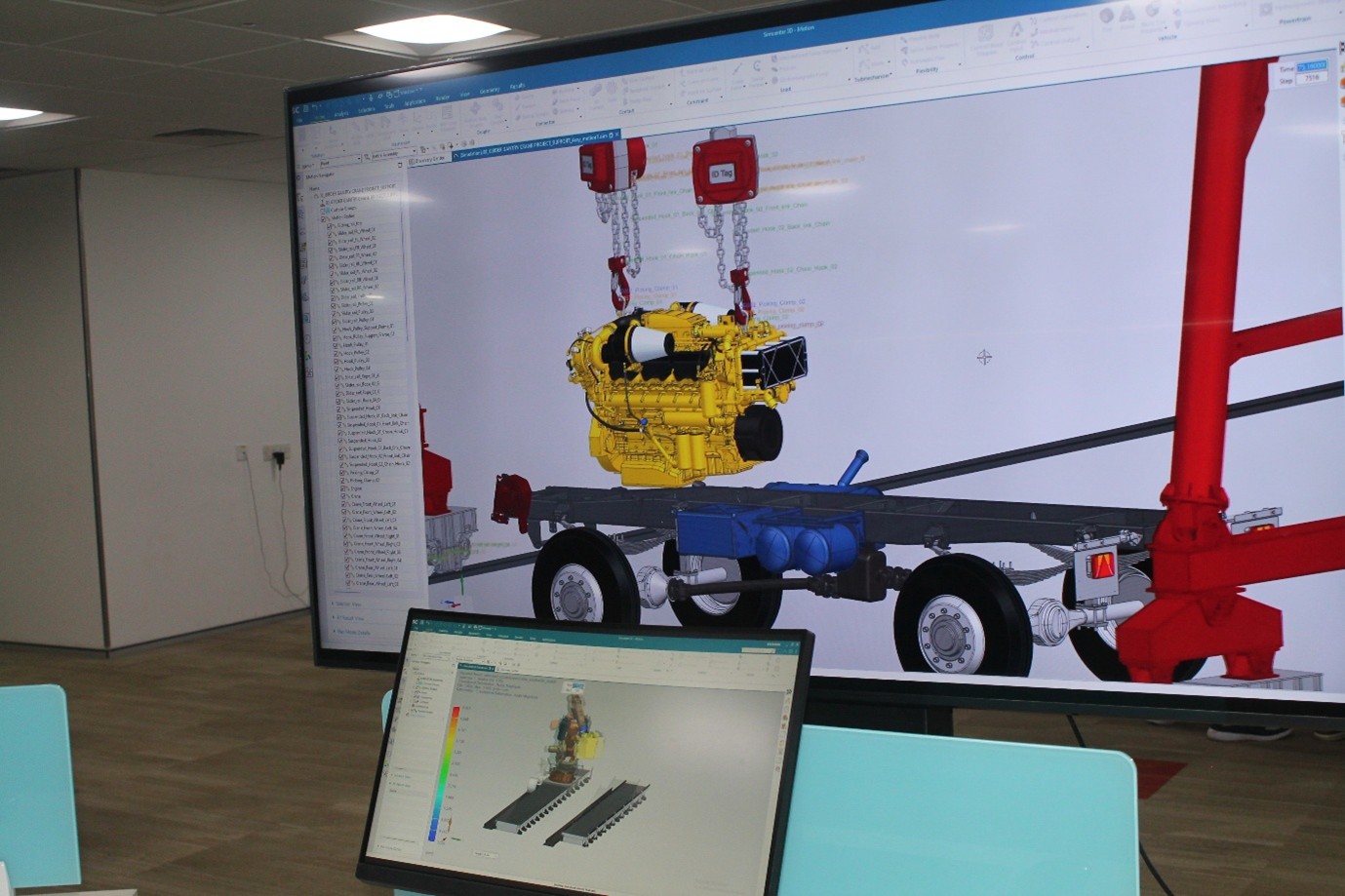

Product Lifecycle Management (PLM) Solutions

The Research Centre for Product Lifecycle Management (PLM) at the Tamil Nadu Smart and Advanced Manufacturing Centre (TANSAM), located in TIDEL Park, Chennai, is a dedicated hub for digital product innovation and lifecycle management. Powered by Siemens Teamcenter, the centre enables industries, MSMEs, startups, and academia to manage products from concept to retirement with digital continuity, collaboration, and efficiency.

PLM Services

- Product Requirements Engineering

- Model Based Systems Engineering

- Bill of Materials Management

- Product Configuration

- Program, Project, and Process Management

- Product Cost Management

- Mechanical Design Management

- E/E Systems Design Management

- Software Design and Asset Management

- Document Management and Authoring

- Lifecycle Visualization

- Simulation and Test Management

- Search and Analytics

- Environmental Compliance & Product Sustainability

Product Requirements Engineering – Benefits

- Manage Requirements

- Trace Requirements

- Align to Plan

- Understand Requirements

Model Based Systems Engineering – Benefits

- Optimize Systems

- Understand Systems

- Verify and Validate

- Continuous Integration

How It Helps Companies

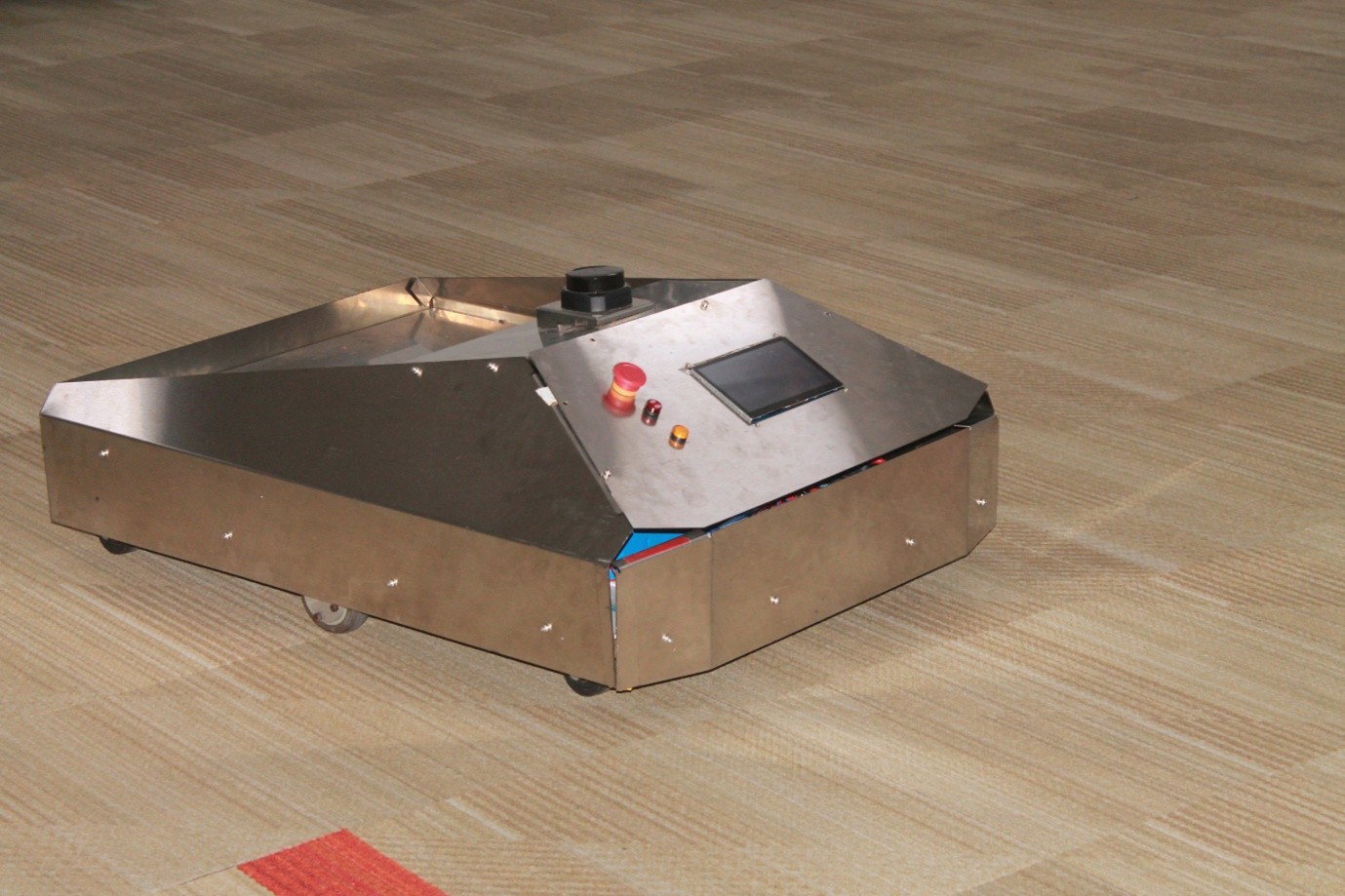

- Streamlined product development – Centralised data management reduces errors and duplication.

- Faster time‑to‑market – Digital workflows accelerate design, testing, and approvals.

- Cost savings – Optimised processes reduce prototyping and manufacturing costs.

- Compliance & quality – Built-in traceability ensures regulatory and quality standards.

- Collaboration at scale – Connects teams across Tamilnadu for unified innovation.

Core Solutions

- PLM Engineering Services – Product data management, BOM creation, workflow automation, CAD integration (NX, Solid Edge).

- Product Requirements Engineering – Requirement capture, lifecycle traceability, compliance management.

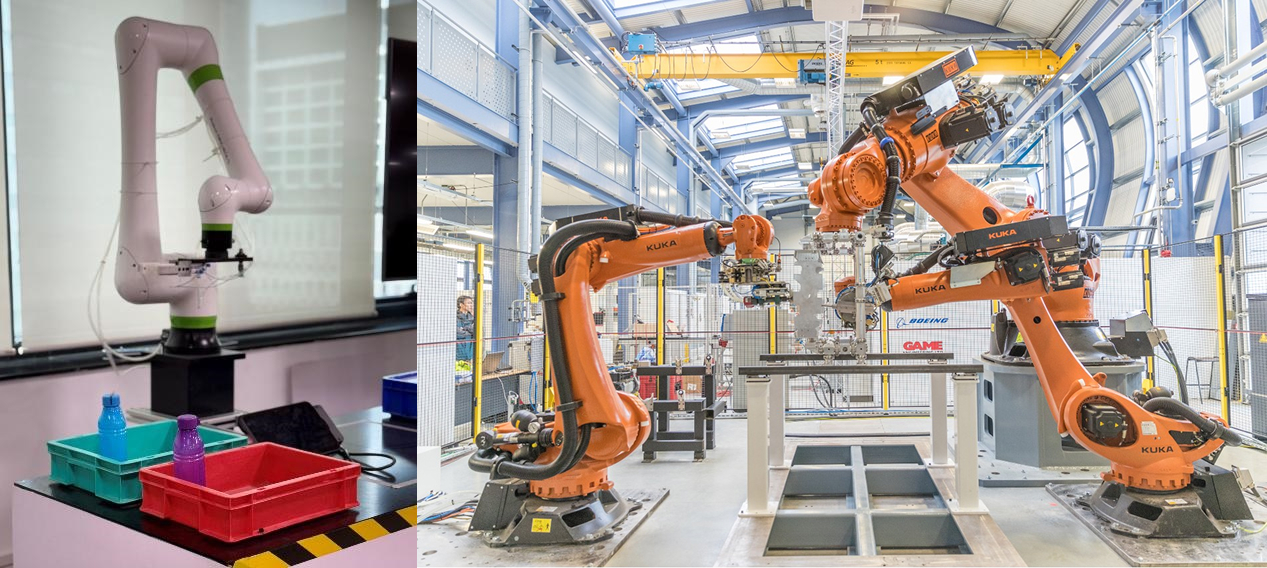

- Model‑Based Systems Engineering (MBSE) – Multi-domain collaboration, system-level modeling, early validation.

Services Offered

- Product Cost Management

- Quality Management

- Supply Chain Management (SCM)

- Process Management

Testimonials

“Teamcenter PLM transformed our engineering workflow. We now manage design changes faster and with complete traceability.” — Automotive MSME, located at Tamilnadu.

“The PLM Centre helped our students understand real-world product development processes, improving their industry readiness.” — Professor, Engineering College, located at Tamilnadu.

Case Study

- A Chennai-based automotive MSME faced delays in managing design changes for critical components.

- Implemented Siemens Teamcenter PLM at the Research Centre.

- Automated BOM updates and streamlined workflows across design and production teams.

- Reduced design cycle time by 30% and improved compliance reporting.

- Outcome: Faster product launches, reduced costs, and improved collaboration across departments.

Frequently Asked Questions (FAQ)

- Q1: Who can access the Research Centre for PLM? MSMEs, startups, enterprises, and academic institutions across Tamil Nadu.

- Q2: What software is used? The centre is powered by Siemens Teamcenter, NX, and Solid Edge.

- Q3: How does PLM benefit MSMEs? It reduces costs, improves efficiency, and ensures compliance with industry standards.