INNOVATION LABS

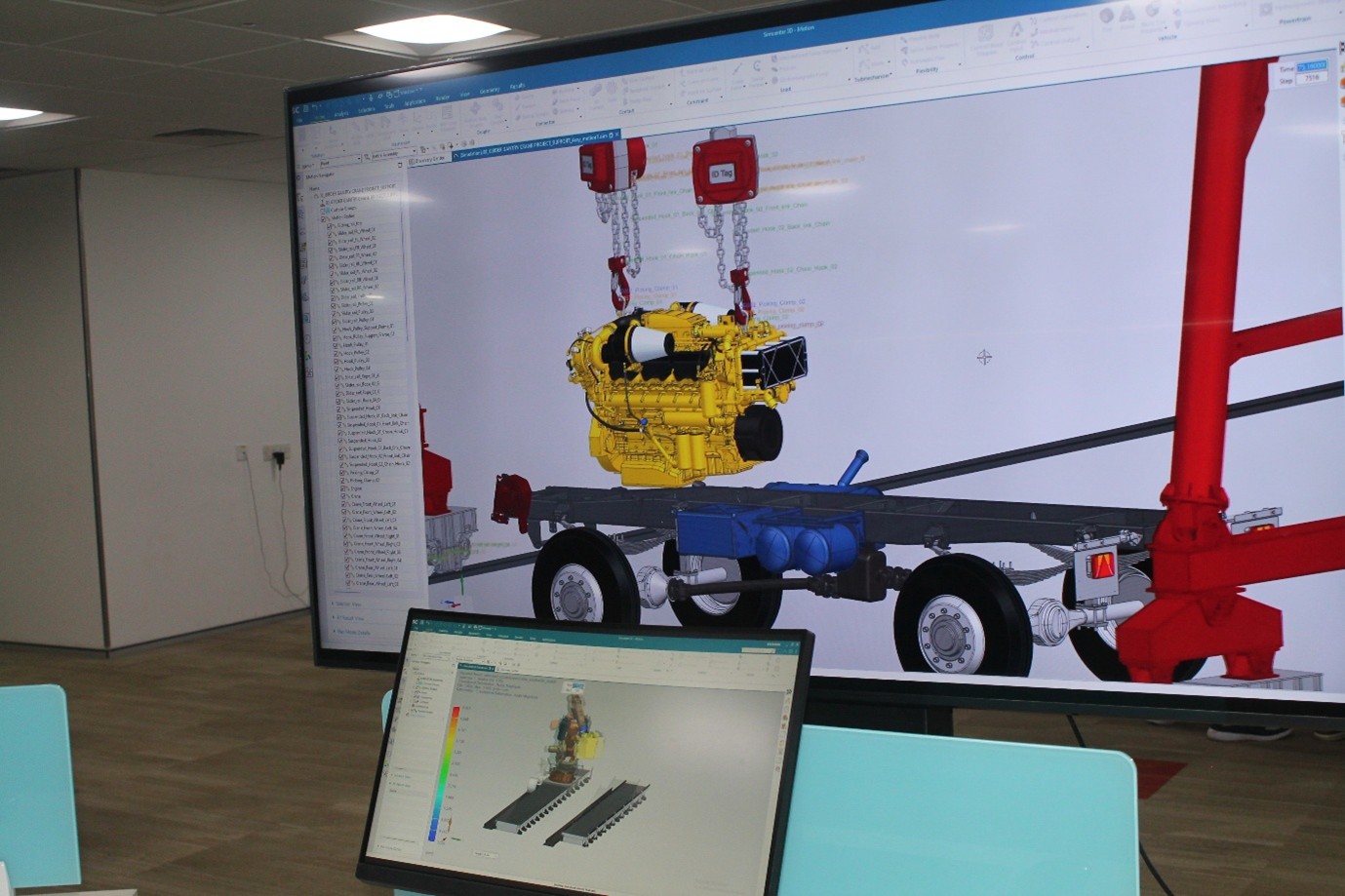

Digital Technologies

Industry 4.0 leverages “Digital Transformational” technologies to create smarter, more efficient, and adaptable manufacturing processes, leading to increased productivity, enhanced quality, and competitiveness.

The technology stack includes AI, Data Science, Business Intelligence, Machine Learning, Industrial Internet of Things, and cloud computing, among others. Artificial Intelligence encompasses Computer Vision, Natural Language Processing, Image Processing, etc.

Implementing an Industry 4.0 strategy in the manufacturing sector involves a systematic approach that aligns technology, processes, and organizational culture.

A few work areas that get enabled with Digital Transformation through AI are:

-

1

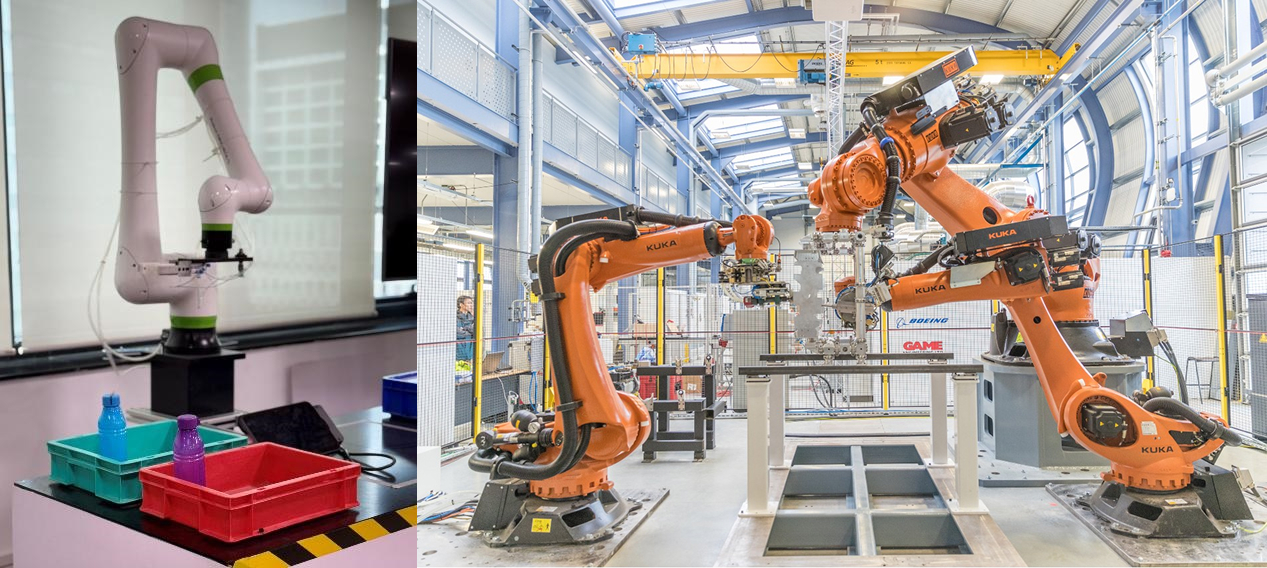

Enhanced Quality Control: AI and machine learning algorithms can analyze quality data in real-time, identifying defects and anomalies during production. This leads to higher product quality and reduced scrap rates.

-

2

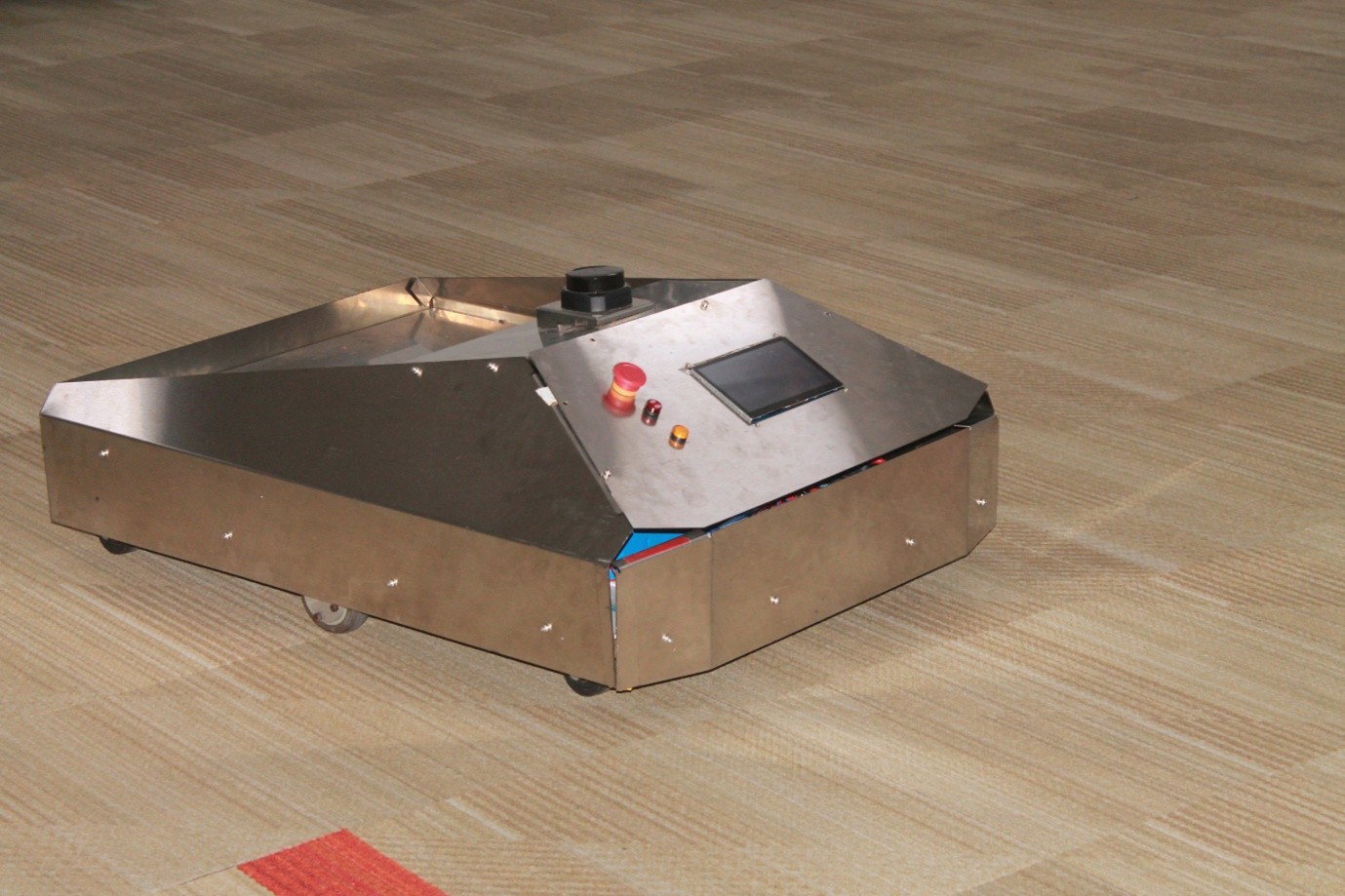

Supply Chain Integration: Enhanced connectivity between suppliers, manufacturers, and distributors improves coordination and efficiency across the supply chain. Real-time tracking and data exchange facilitate faster responses to changes or disruptions.

-

3

Predictive Maintenance: Using AI and data analytics, manufacturers can predict when equipment is likely to fail or require maintenance. This proactive approach minimizes downtime, reduces maintenance costs, and extends the life of machinery.

-

4

Data Analytics: Advanced data analytics provides insights into production processes, customer behavior, and market trends. This enables manufacturers to optimize operations, reduce waste, and tailor products to customer needs.

-

5

Energy Efficiency: Smart technologies enable better energy management in manufacturing operations, leading to reduced energy consumption and lower operational costs.

-

6

Smart Sensors: IoT devices and smart sensors collect real-time data from machinery and operations. This helps monitor performance, enabling informed decision-making and rapid responses to issues.

-

7

Digitization, Data Integration, Management: Establish a robust data strategy to collect, store, and analyze data from various sources. Utilize data management tools to ensure data quality and accessibility across the organization, creating a centralized and authoritative data repository.