INNOVATION LABS

Centre for Predictive Engineering Analytics

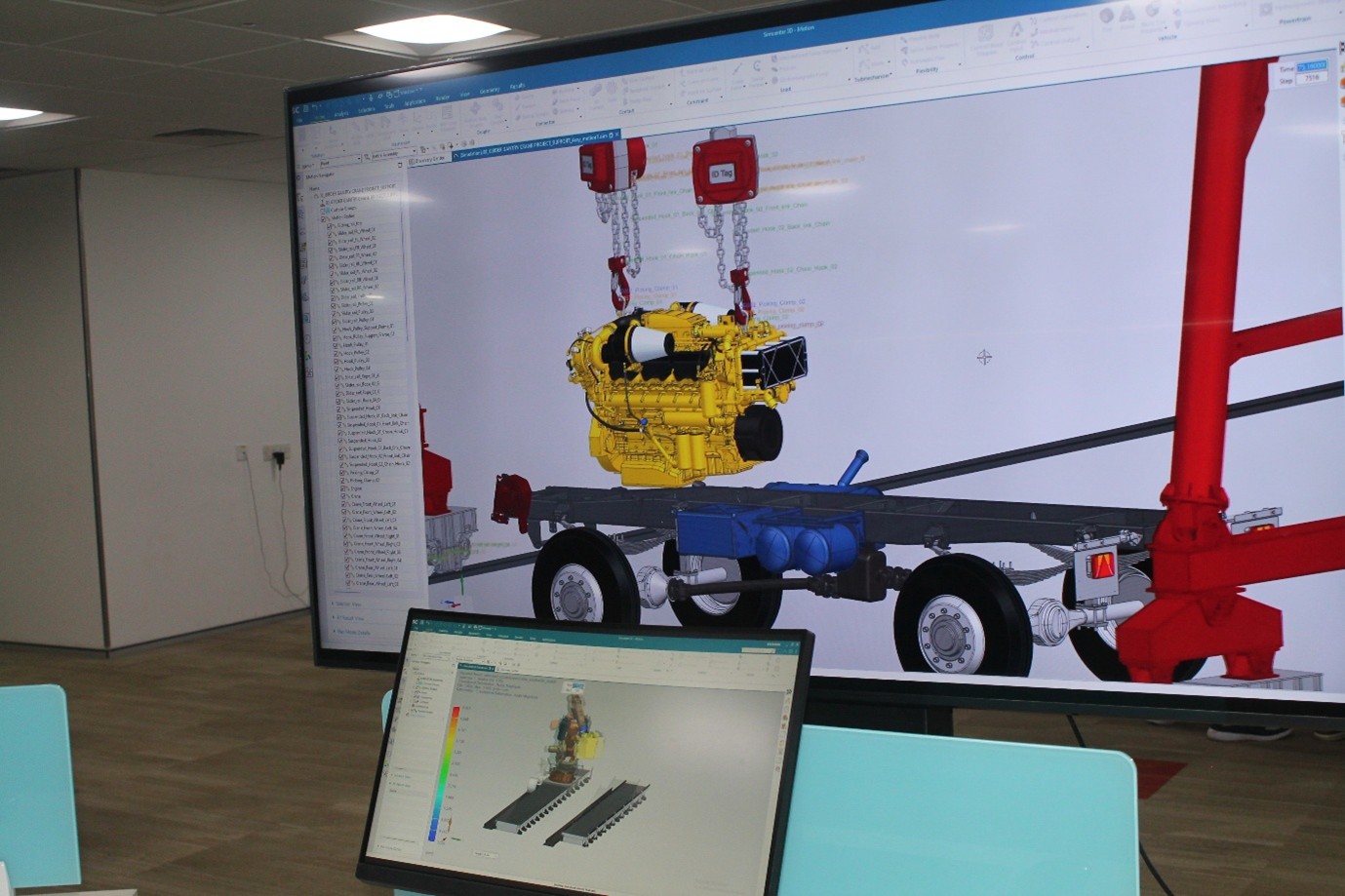

The Predictive Engineering Lab at TANSAM (Tamil Nadu Smart and Advanced Manufacturing Centre), located at TIDEL Park, Chennai, is a cutting‑edge facility for simulation, modelling, and predictive analysis. It empowers MSMEs, startups, and students across Tamil Nadu to design, test, and validate products virtually before manufacturing, reducing costs and accelerating innovation.

Key Objectives

- To predict the behavior of a system under different loading conditions

- To identify potential failure modes

- To optimize the design of a system for performance, safety, or cost

- To reduce the need for physical prototypes

- To improve the understanding of a system's behavior

Domains We Have Worked For

- FEA – Finite Element Analysis

- CFD – Computational Fluid Dynamics

- Multi Body Dynamics

- Kinematics

- Noise, Vibration, Shock

- Thermal

How It Helps Companies

- Reduced prototyping costs: Virtual simulations eliminate the need for multiple physical prototypes.

- Faster time‑to‑market: Predictive modelling accelerates design validation.

- Improved reliability: Simulations identify weaknesses before production.

- Local impact:Across Tamilnadu MSMEs gain affordable access to advanced predictive tools.

- Academic collaboration: Students gain hands‑on exposure to simulation software and Industry 4.0 workflows.

Core Solutions

- Finite Element Analysis (FEA) – Structural, thermal, and vibration simulations.

- Computational Fluid Dynamics (CFD) – Flow and heat transfer modelling.

- Multiphysics Simulation – Integrated analysis across mechanical, electrical, and thermal domains.

- Digital Twin Integration – Real-time predictive modelling linked to IoT data.

Services Offered

- Simulation and modelling consulting

- Product validation and optimisation

- Predictive engineering training programs

- Collaborative projects with MSMEs and universities

Testimonials

“The Predictive Engineering Lab helped us validate our designs virtually, saving us time and money.” – MSME Partner, located at Tamilnadu.

“Students gained practical skills in FEA and CFD, making them job-ready for Industry 4.0 roles.” – Professor, Engineering College, located at Tamilnadu.

Case Study

- A Madurai-based MSME wanted to optimise the design of a pump system.

- Engineers used CFD simulations to analyse fluid flow and pressure distribution.

- FEA modelling validated structural strength under varying loads.

- A digital twin was created to monitor real-time performance.

- Outcome: Reduced energy consumption by 20%, improved reliability, and lowered production costs.

Frequently Asked Questions (FAQ)

- Q1: Who can access the Predictive Engineering Lab? MSMEs, startups, enterprises, and academic institutions across Tamil Nadu.

- Q2: What technologies are used? The lab uses Siemens NX, Solid Edge, FEA, CFD, and digital twin platforms.

- Q3: How does it benefit MSMEs? It reduces costs, accelerates product validation, and improves reliability.