TAMIL NADU SMART AND ADVANCED MANUFACTURING CENTER - (TANSAM)

Center of Excellence powered by SIEMENS

Center of Excellence powered by SIEMENS

Driving innovation, sustainability, and advanced technology for global growth.

.png)

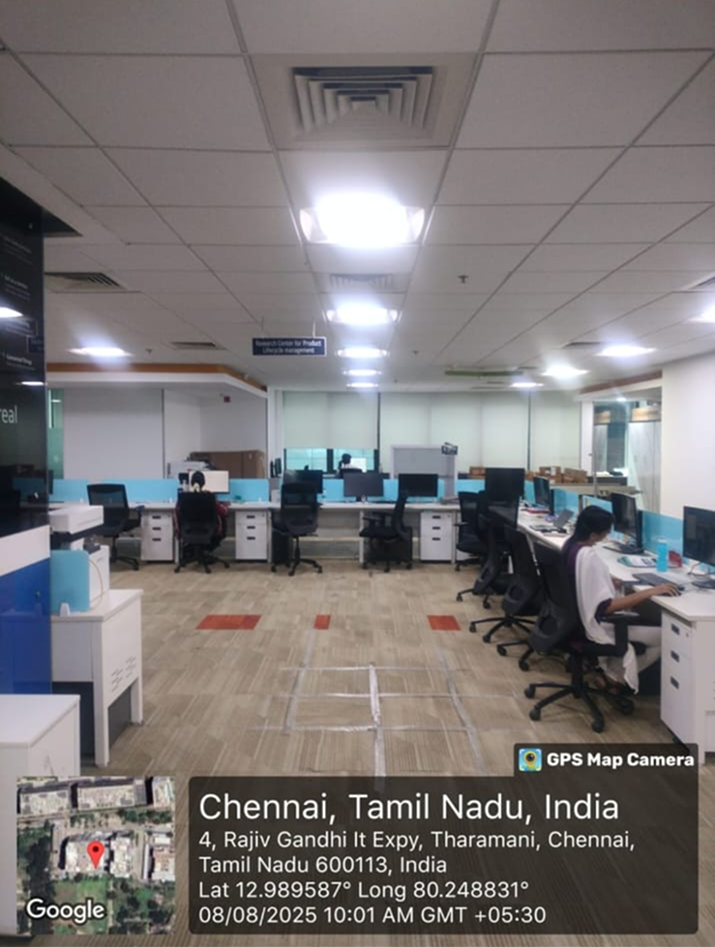

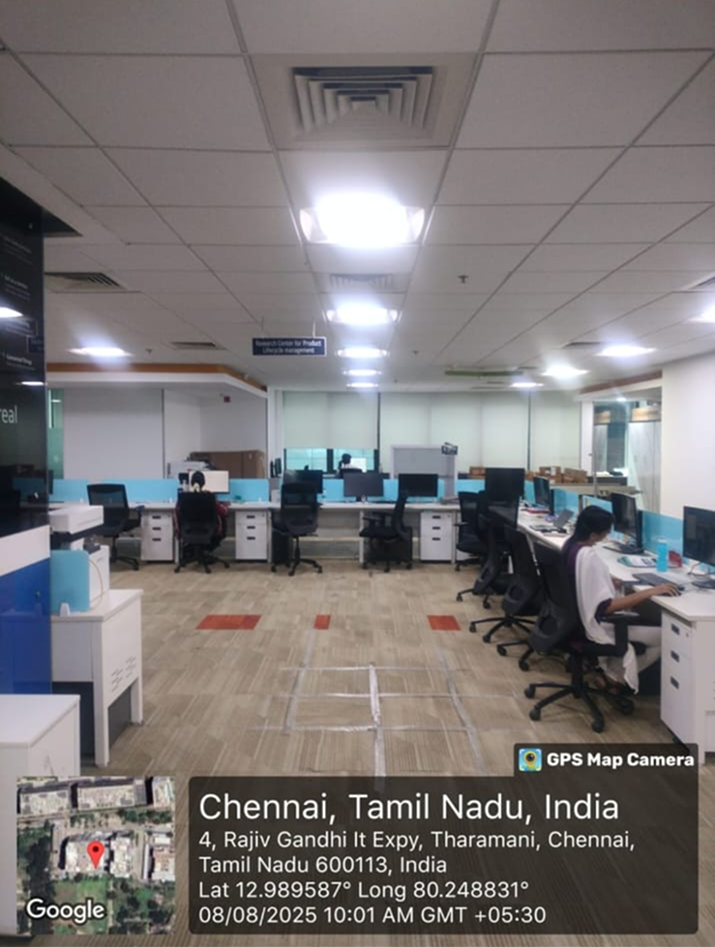

TANSAM (Tamil Nadu Smart and Advanced Manufacturing), powered by Siemens, is the state’s of the arts Industry 4.0 Centre of Excellence. Located at Tidel Park, Chennai, TANSAM helps industries, MSMEs, and academic institutions adopt future‑ready technologies such as IoT, digital twins, AI, AR/VR, and smart factory solutions.

Inaugurated on 8 November 2022 by Honourable Chief Minister of Tamil Nadu, Thiru. M.K. Stalin. Established as a Section 8 company under TIDCO to drive industrial growth,a global leader in smart manufacturing solutions.

.png)

TANSAM Product Innovation Center uses Siemens tools to accelerate efficient, creative product development.

TANSAM Predictive Engineering Center uses Siemens tools to simulate, analyze, and optimize products.

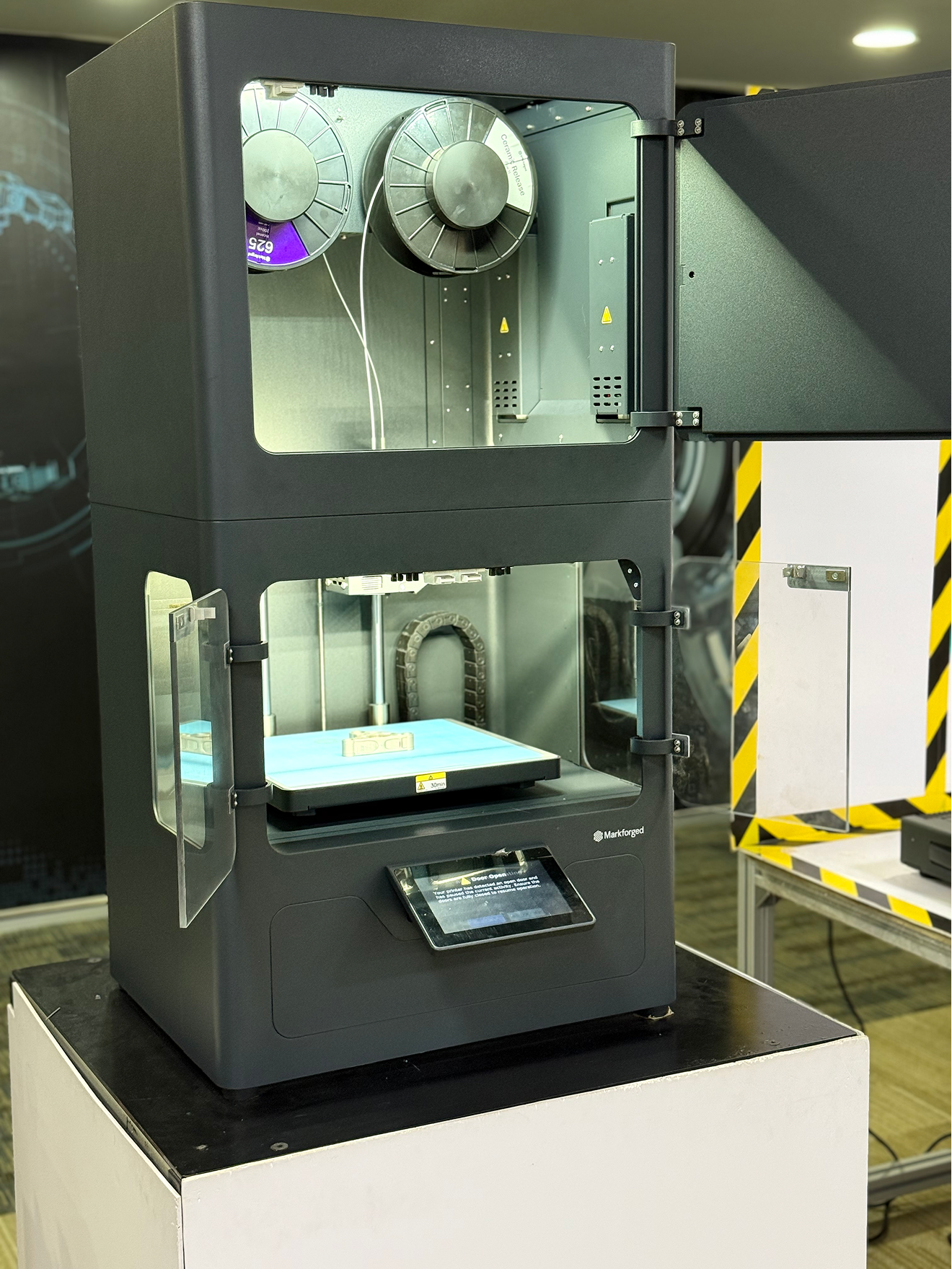

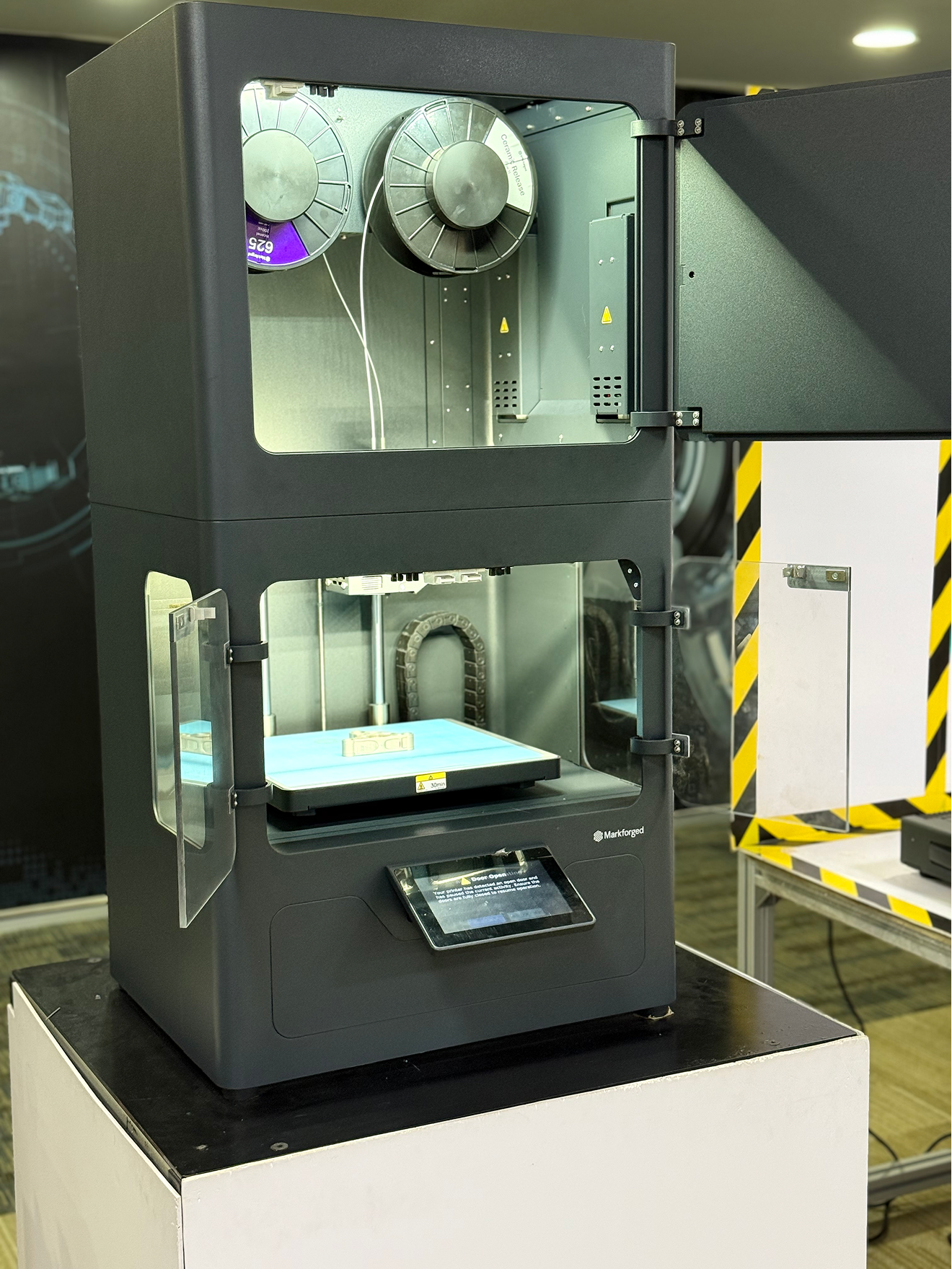

TANSAM with Siemens powers precision manufacturing through reverse engineering and 3D metal printing.

TANSAM Smart Factory uses Siemens Industry 4.0 tools to optimize and transform manufacturing.

TANSAM Asset Performance uses advanced engineering & computing methods to determine predictive and preventive asset performance.

TANSAM Industrial IIoT & Equipment performance center uses edge computing, IIoT, and automation tools to enhance efficiency and productivity at the shop floor.

TANSAM PLM Center uses Siemens Teamcenter to streamline product lifecycle, collaboration, and innovation.

TANSAM AR/VR/MR Lab develops immersive simulations enhancing training, learning, and real-world workflows.

TANSAM Digital Technologies center uses AI & ML techniques for vision computing, digitization, and advanced computing needs.

At TANSAM, innovation and collaboration shape the future of smart manufacturing in Tamil Nadu. Recent industry partnerships, technology showcases, and advanced training programs highlight our commitment to empowering businesses and individuals with the tools of Industry 4.0.

Discover TANSAM’s latest milestones, partnerships, and industry breakthroughs. From new training programs to smart factory innovations, our updates show how we are shaping the future of manufacturing in Tamil Nadu.

A hands-on training program covering IoT, AI, and Robotics for MSME engineers and managers.

Showcasing TANSAM’s latest projects in virtual reality training, holographic simulations, and digital factory planning.

Honourable Minister Thiru Ma. Subramanian launched a mobile app for field monitoring developed by TANSAM.

A one-day summit bringing together experts to showcase AI, robotics, and digital twin innovations with live demos.

At TANSAM, innovation and collaboration shape the future of smart manufacturing in Tamil Nadu. Recent industry partnerships, technology showcases, and advanced training programs highlight our commitment to empowering businesses and individuals with the tools of Industry 4.0.

Discover TANSAM’s latest milestones, partnerships, and industry breakthroughs. From new training programs to smart factory innovations, our updates show how we are shaping the future of manufacturing in Tamil Nadu.

A hands-on training program covering IoT, AI, and Robotics for MSME engineers and managers.

Showcasing TANSAM’s latest projects in virtual reality training, holographic simulations, and digital factory planning.

Honourable Minister Thiru Ma. Subramanian launched a mobile app for field monitoring developed by TANSAM.

A one-day summit bringing together experts to showcase AI, robotics, and digital twin innovations with live demos.

TANSAM partners with leading manufacturing enterprises, MSMEs, and startups to accelerate digital transformation. Our clients leverage IoT, AR/VR, AI, and digital twin technologies to build smarter factories and reduce time-to-market.

We collaborate with universities, research institutions, and faculty to advance Industry 4.0 education. Through courses, certifications, and joint research, academic partners gain hands-on exposure to smart manufacturing technologies and prepare students for future-ready careers.

Joy University is proud to have collaborated with TANSAM for setting up an AR/VR Centre of Excellence that has empowered our students with hands-on exposure to cutting-edge technologies, product simulations, and real-time industry-relevant solutions. This collaboration has enabled students to win prizes at national-level hackathons and showcase their skills in prestigious events, boosting innovation and employability.

TANSAM has been actively collaborating with JSW Steel for the past two years, successfully conducting technical training programs and developing a VR module for Gear Box Assembly of Screw-down gearbox assembly, which has been of great value to our organization. We deeply appreciate TANSAM’s professional approach, commitment, and innovation in delivering industry-relevant solutions and look forward to achieving more milestones together.

Renault Nissan Automotive India Pvt Ltd (RNAIPL) had the privilege of collaborating with TANSAM to establish an Innovation Center at our plant that has become a thriving hub for testing and scaling employee-driven ideas. With TANSAM’s expertise and support, we successfully developed and implemented solutions in IIoT, computer vision, and factory simulations—enhancing our manufacturing capabilities. Their collaborative spirit and technical proficiency have been key in transforming concepts into real-world applications and accelerating our digital transformation journey.

Students of Annai Vailankanni College of Engineering successfully completed their internship at TANSAM in Artificial Intelligence/Machine Learning (AI/ML) and Full Stack Development, gaining hands-on experience with industry-relevant tools, technologies, and projects. The mentorship and guidance provided by TANSAM helped students enhance programming skills, problem-solving abilities, and professional confidence, effectively preparing them for IT careers and research opportunities. Several students were successfully placed in reputed companies, including opportunities within TANSAM itself.

An innovation done by our team has been recognized in the TPM Event (Total Productive Maintenance) organized by CII. Our team has won the Silver Medal. The system implemented provides a robust, low-cost, and highly accurate solution for quality control. By integrating AI, Computer Vision and PLC automation, significant failure modes in the engine assembly process, has been eliminated. The system provides real-time validation of operator movements. This solution addresses a critical quality risk in the engine assembly line.

Principal, Seshan from our team had participated in the event conducted this week along with few members from Renault Nissan.

Stay updated with the latest news, events, and Entrepreneurship Development!